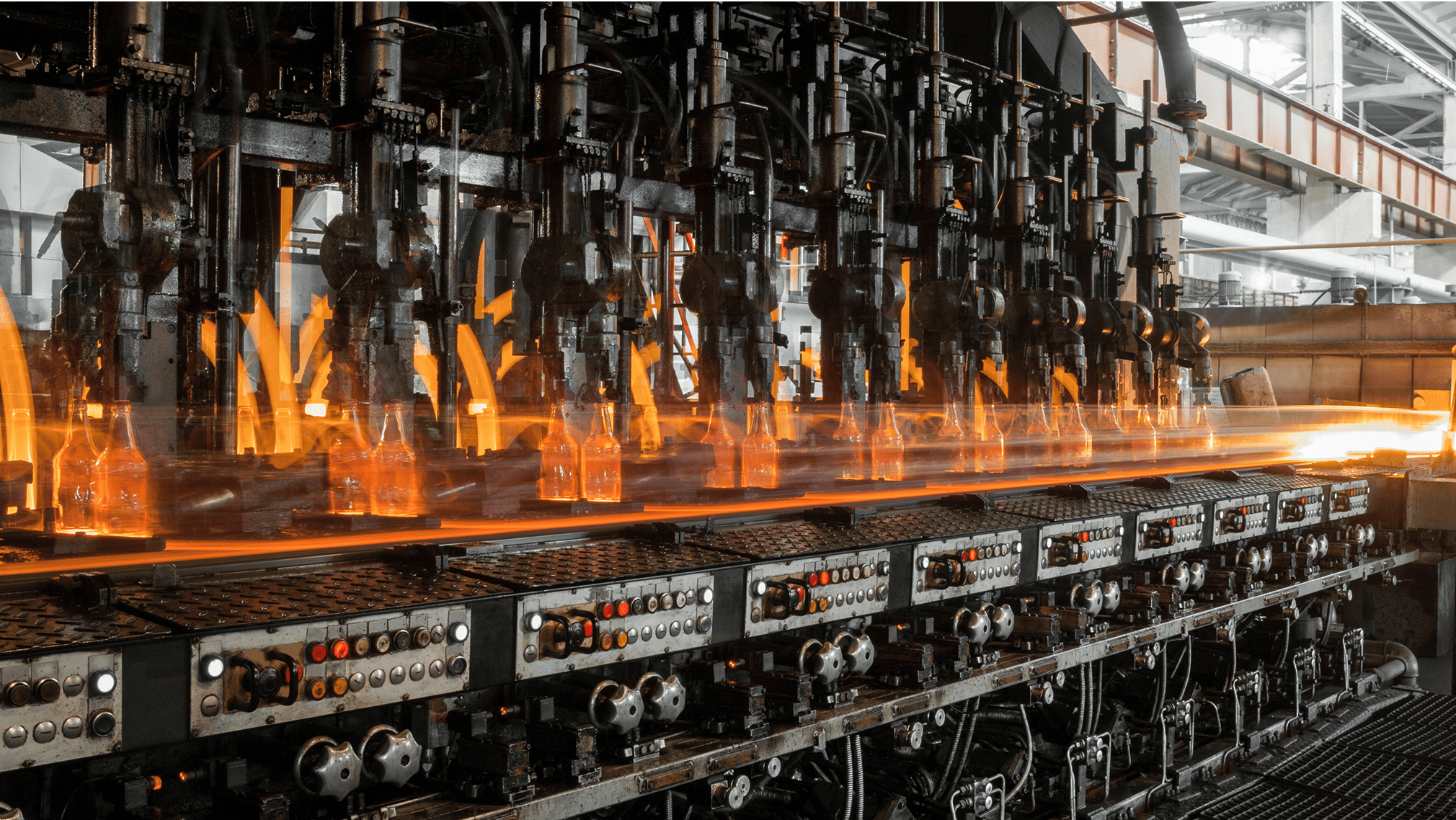

Glass

Our offer for glassmaking industry

Glass manufacturers today face increasing pressure for efficiency, sustainability, and market competitiveness.

Business success under these conditions demands reliable support in the critical area of refractory linings for glass production. Our ambition is to be more than just a supplier of refractory materials—to act as a strategic, dependable technology partner that relieves your company of the complexities inherent in furnace infrastructure maintenance. We provide support precisely where your organization needs it: from engineering studies and collaborative selection of the most effective material and installation technologies, to worldwide logistics, installation (or its supervision), and post-installation support. We believe that our consistently high-quality products and service, combined with comprehensive backing, will minimize production downtime and enable you to become more competitive and sustainable through our refractory expertise. Discover our full offering for the glass-making industry, covering a wide range of services and products—chamotte, andalusite, mullite, and high-alumina refractories, as well as thermal-insulation solutions.

What we can do for you

We design

- Support for designing and calculating refractory‐material requirements.

- Design and selection of optimal ceramic solutions and shapes based on producibility.

- Preparation of shop drawings for premounting and installation of supplied products.

- Thermal calculations for selected lining components.

We manufacture and supply

- Chamotte and andalusite bricks for working and protective layers in the glass furnace (bottom, walls, flue channels, under‐chamber grates).

- Mullite shapes for use in the regenerator, in high‐temperature zones (upper fill sections and dome operating up to 1700 °C).

- Insulating bricks and castables for furnace walls, domes, and regenerator chambers.

- Mortars and a wide range of conventional, low‐cement, and cement‐free castables.

We install

- Refractory linings by our specialist installation subsidiary PCO Serwis.

- Repairs and rebuilds of furnaces and regenerators.

- Technical consulting.

Furnaces and high-temperature industrial equipment

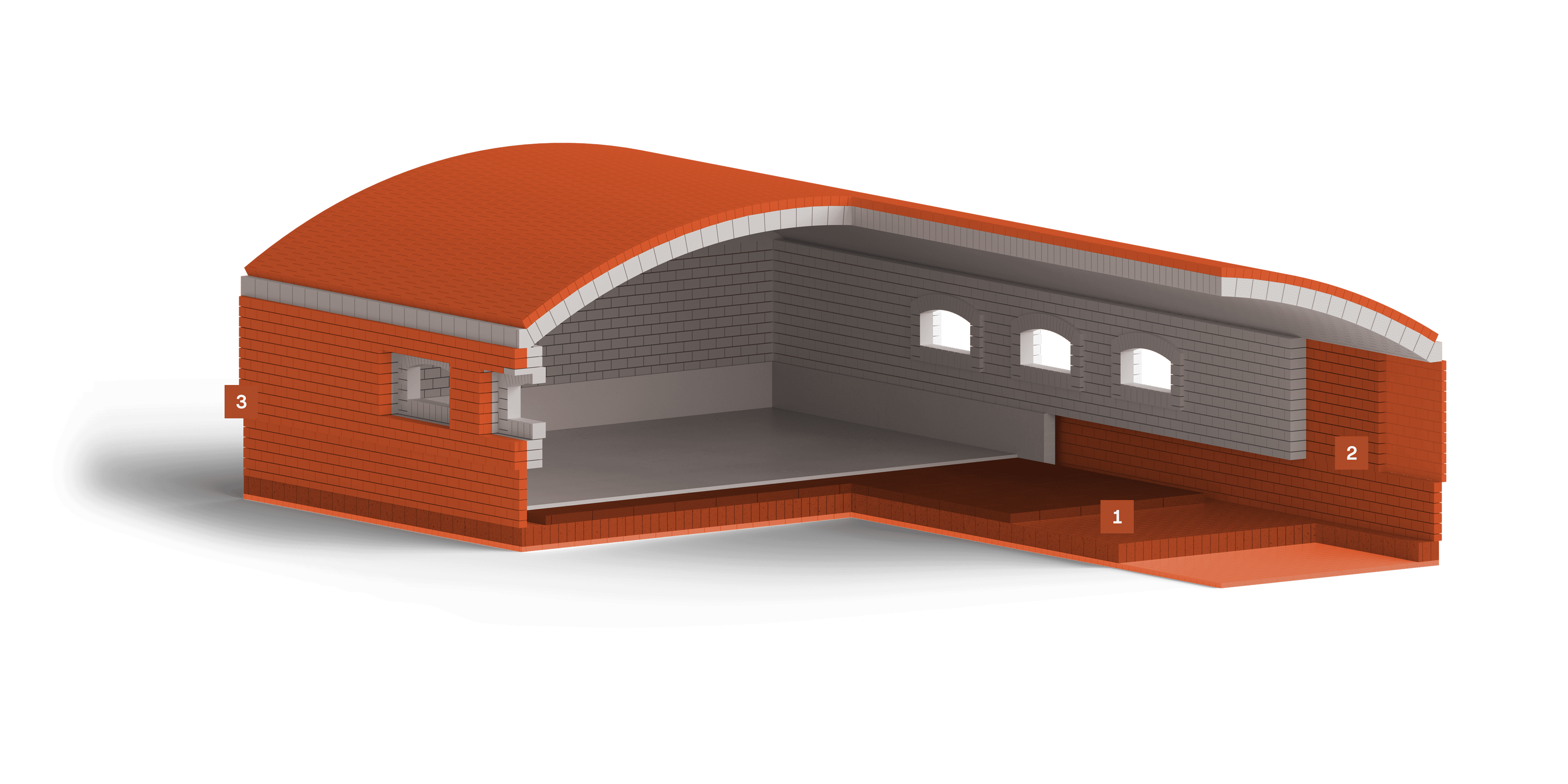

Glass tank

The glass tank is a device in which a mixture of solid raw materials is melted into a liquid glass mass. The conditions of this production process require a multilayer ceramic lining using formed refractory and insulating bricks. Aluminosilicate materials are used throughout almost the entire structure, except in zones located below the bath level, where fused cast AZS blocks and silica‐based products operate. One of the main challenges for the refractory lining in the glass tank is the severe erosion of the working layers, caused by the aggressive chemical environment and extremely high temperatures. Meanwhile, the insulating layers are primarily subjected to mechanical loads from the weight of the charge as well as from high temperatures. PCO offers a comprehensive range of aluminosilicate materials for glass furnaces, including chamotte products, high‐alumina items such as ground plates and blocks, bricks, and shapes. We supply plates up to 650 mm in the length of the longest side. For multilayer systems, we perform pre-assembly to ensure a fast and trouble‐free installation.

Scope of offer: Lining design Refractory products supply Lining installation services

The refractory lining of the glass tank floor is subjected to significant mechanical loads and leaching caused by the flow of molten glass. For this reason, its construction uses several layers of formed products and a bedding layer of refractory castable. Selecting materials with high mechanical strength and appropriate corrosion resistance is critical for trouble‐free operation. In the layer in direct contact with the glass melt, fused‐cast AZS blocks are used. Below this layer, products from the ANDALUX and MULITEX families are installed; these offer precise dimensional accuracy and high resistance to both temperature and pressure. The deeper, load‐bearing and insulating layers can be made from SUPERTON, NORMATON, and ISOLUX products, which provide the necessary level of insulation and structural stability.

The refractory lining of the glass tank walls is exposed to high temperatures, leaching by the molten glass, and attack from aggressive vapors. A typical lining consists of multiple layers of dense products in order to minimize the risk of chemical reactions and material erosion. In the working lining, fused‐cast products are used in the lower levels and silica‐based refractories in the upper sections that do not come into direct contact with the molten glass. In the insulating layers, dense high‐alumina ANDALUX products and chamotte SUPERTON refractories are employed; both offer high mechanical strength and stability under demanding process conditions.

Lightweight insulating layers are placed as the final lining layer (behind the working and dense insulating layers) and do not come into direct contact with the molten glass. However, they are still exposed to high temperatures and mechanical loads. Depending on the size of the furnace, one or more layers of lightweight insulation are used, and it is essential to select them based on both mechanical strength and thermal conductivity requirements. PCO Żarów manufactures insulating bricks with increased density to provide greater mechanical strength, as well as standard lightweight bricks designed for improved thermal conductivity. This allows precise tailoring of the insulation layers to the specific demands of each project, ensuring effective thermal protection and extending the service life of the entire structure.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryWhat refractory lining layering system will be best for a flat glass furnace, and what for a container glass furnace?

What technical data and experience from previous furnace campaigns should be monitored and considered when selecting refractory materials for the next overhaul?

How should the logistics process be managed during a furnace overhaul to secure time for superstructure pre-assemblies and avoid storing too many pallets of furnace ceramics on the construction site?

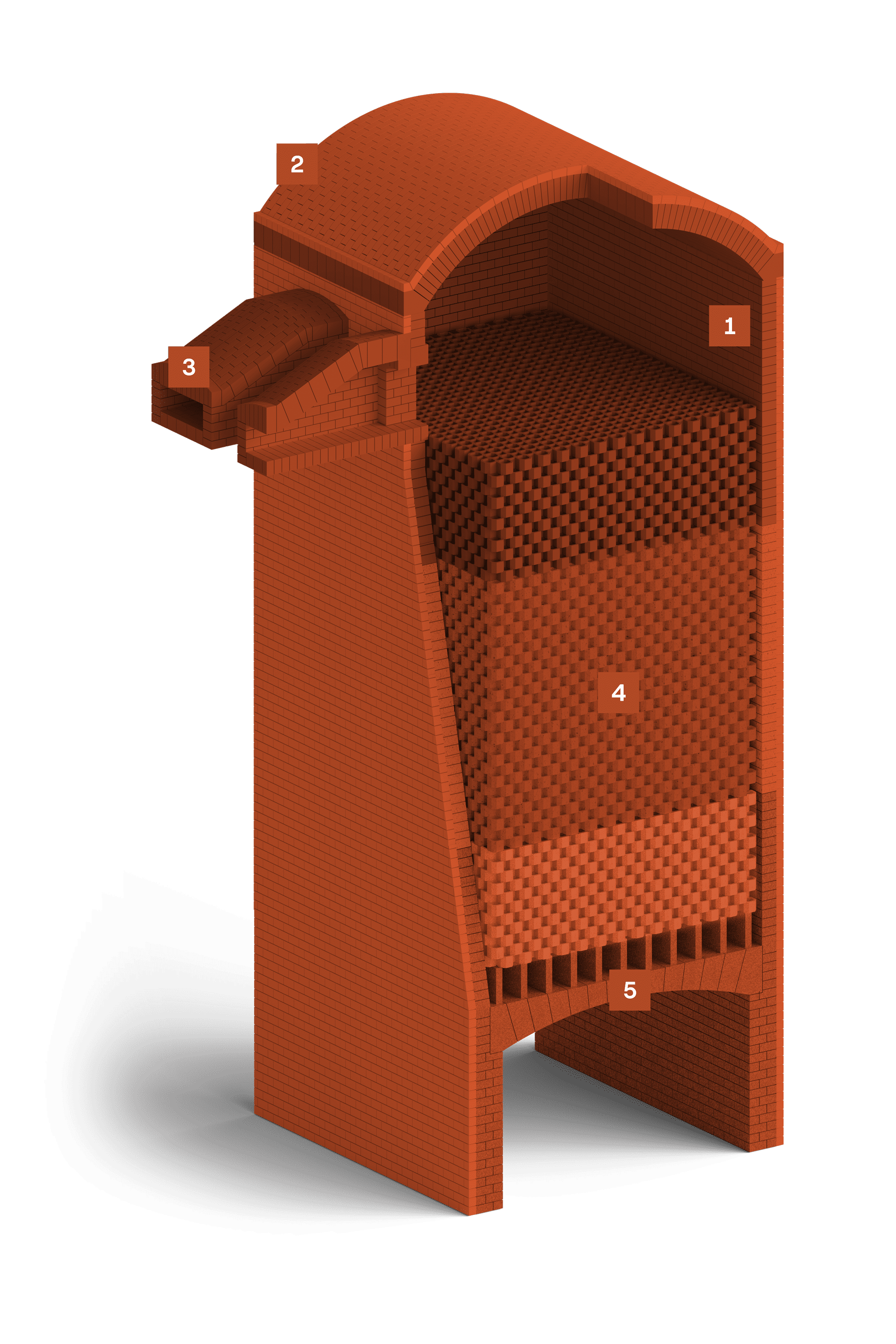

Regenerator

Regenerators for glass tanks recover heat from flue gases by using it to preheat the combustion air feeding the burners. They operate cyclically—in alternating pairs—at temperatures reaching up to 1500 °C. This cyclic operation subjects the refractory lining to continuous temperature swings, alternating between heating and cooling. During the heat‐recovery cycle, the primary risk factor for the ceramic lining is abrasive attack by the process gases and dust. The working layers (dome, walls, and chamber fill) must use refractories that resist aggressive process particulates, sulfur compounds, and hydrocarbons, as well as endure repeated thermal cycling. The insulating layers of the dome and walls are mainly exposed to mechanical loads due to the regenerator’s structure. PCO offers a complete range of aluminosilicate refractories for regenerator linings. Our portfolio includes corundum, mullite, and andalusite bricks, as well as chamotte products, plus formed insulating shapes for protective layers. We also provide engineering services—liner design support, premounting of chamber fill and under‐chamber grate sections—to ensure reliable, efficient installation.

Scope of offer: Lining design Refractory products supply Lining installation services

The upper dome area of the regenerator operates under exceptionally demanding conditions—very high temperatures and intense erosive action from the flue gases. The working lining in this section consists of a single layer of formed refractory shapes, which must exhibit outstanding thermomechanical properties and high resistance to chemical corrosion. The recommended solution is to use bricks from the MULITEX family—fused mullite materials with a low creep rate and high refractoriness. These perform well not only in the dome but also in the upper layers of the chamber fill (regerenator “chimney” bricks), where they form a stable core of the regenerator’s structure.

The outer layer of the regenerator’s dome and walls is exposed primarily to the effects of lining leaks and high temperatures. In this layer, formed insulating bricks and insulating refractory castables (sprayed for the final layer) are typically used. The key aspect here is to provide a high level of insulation while maintaining mechanical stability. An excellent choice is the higher‐density insulating bricks from the ISOLUX series, which combine high strength with good insulating properties, as well as ISOGUN spray-applied castables, which allow for rapid and efficient installation of protective layers.

Regenerator ports are channels that transport air (including exhaust gases) to the burners and are located in the upper part of the structure. Because aggressive gases and high temperatures flow through this zone, the materials used here must exhibit exceptional resistance to infiltration and chemical corrosion. The most common choice is fused‐cast MULITEX products, which provide dimensional stability and long‐term resistance to thermal and chemical stresses, ensuring reliable regenerator performance.

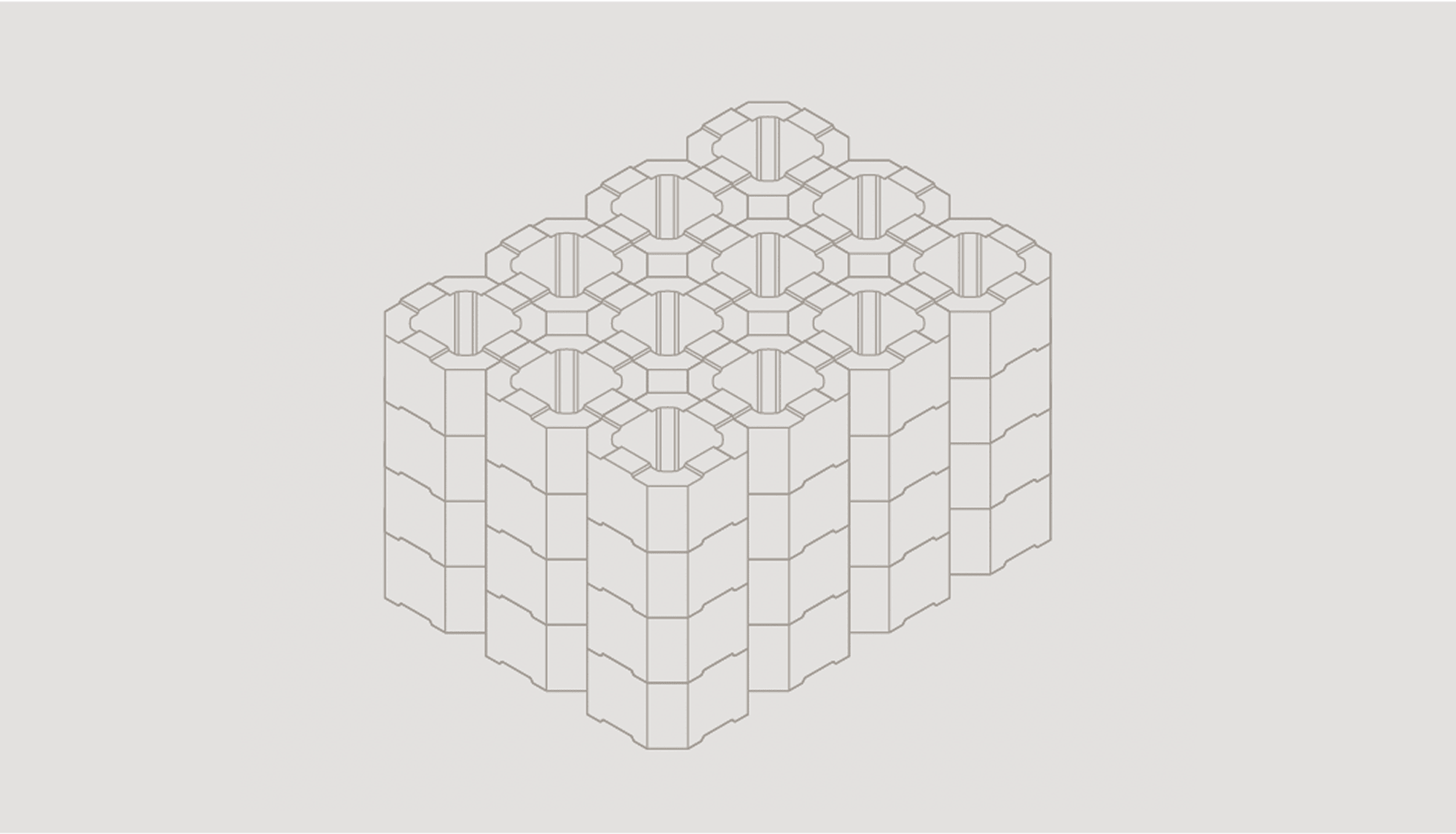

The regenerator chamber is typically filled using pot‐shaped elements made from chamotte, andalusite, or mullite raw materials—chosen according to the zone and its specific loads. In the lower sections of the fill, mechanical stresses dominate (as these elements support the upper layers). Here, products from the SUPERTON, MULITEX, or ANDALUX series perform well. In the middle areas, alkali vapors often condense, accelerating chemical corrosion. Preferred products in this zone are from the ANDALUX line, distinguished by low porosity and high chemical‐attack resistance. The upper layers—subject to the highest temperatures and most aggressive flue gases—are best protected with high‐alumina mullite shapes from the MULITEX family, which resist thermal deformation and melting.

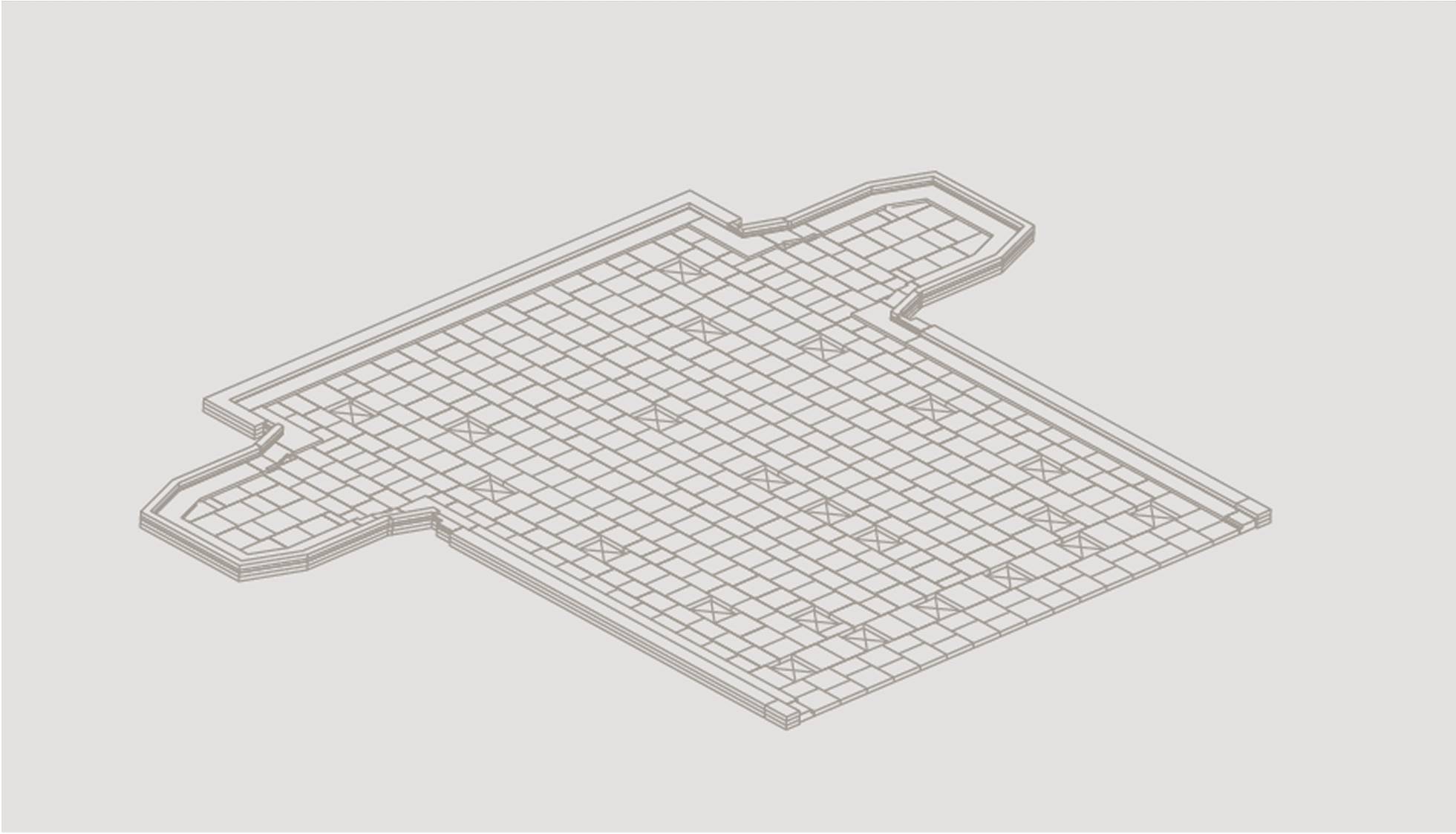

The supporting arch (rider arch), located beneath the regenerator chamber, is a critical component that carries the entire ceramic fill structure. Therefore, its stability and precise installation are especially important. Before the arch is installed in the furnace, a dry‐fit pre-assembly is performed to verify dimensional accuracy against the design. PCO provides this service as standard. The supporting arch is made from a single layer of formed elements, laid in a wedge (row) pattern. In this demanding zone, SUPERTON or ANDALUX products are most suitable, valued for their high mechanical strength and long‐term stability under intense thermal and mechanical loading.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryWhich material should be used to minimize and slow down the creep of the refractory lining, especially in the upper zones of the regenerator?

How to manage the process and which material to install in the regenerator crown area to limit corrosion from sodium hydroxide (the formation of "flakes" of nepheline)?

What’s the most suitable refractory zoning arrangement for regenerator to best withstand the thermal shock and accommodate different materials thermal expansion?

Why choose PCO?

We help solve the most challenging tasks – we can produce shapes with complex geometries for special applications

Product and service portfolio tailored to the needs of the glassmaking industry

Easy project management and reduced risk – a single supplier of refractory services and materials

Selected Products and Services for the Coke Industry

MULITEX AL75HM

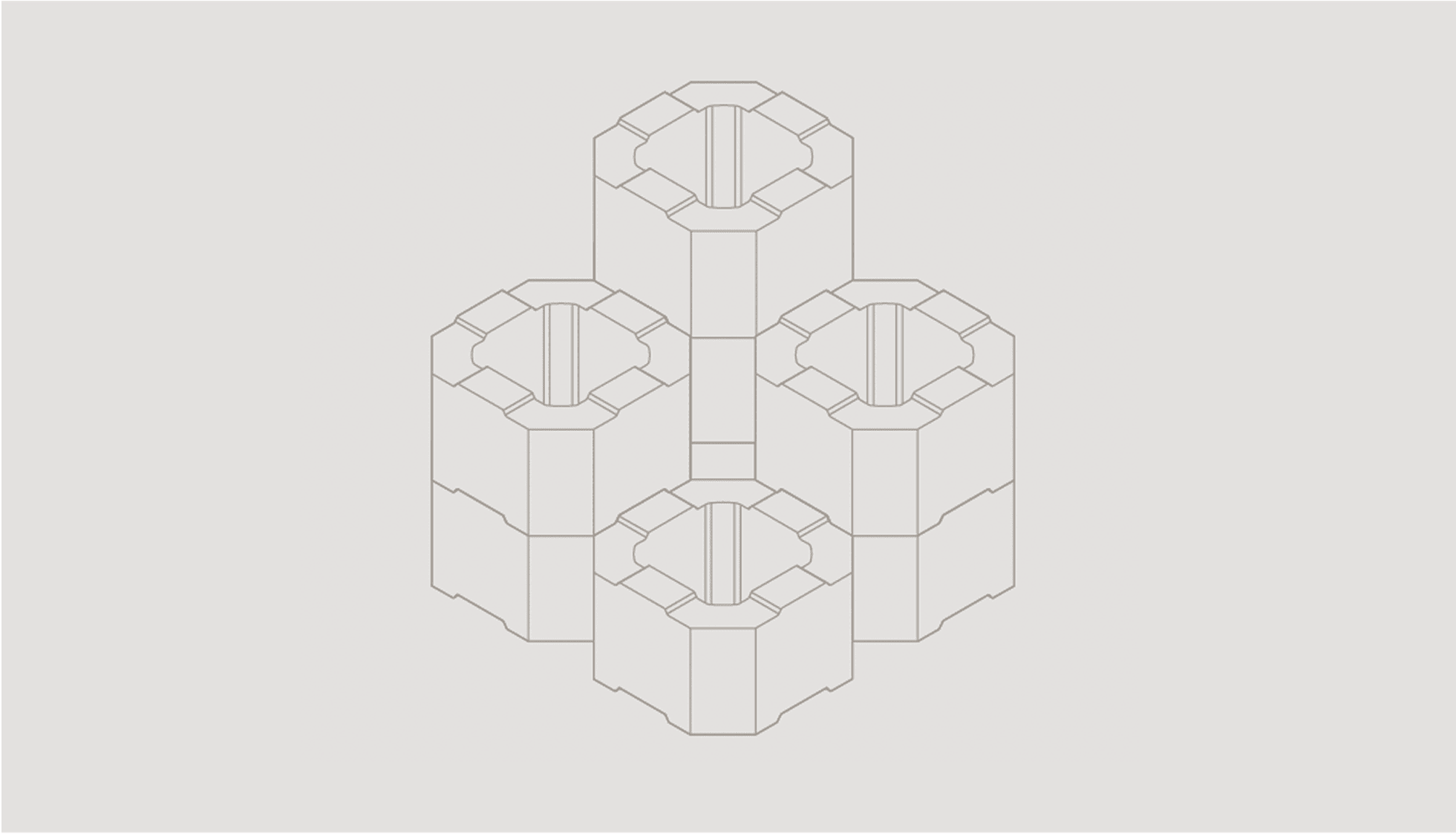

Calibrated Regenerator Shapes

Pre-Assembly of Tank Floor and Dome Linings

Contact us

Please select the option that best describes the subject you want to discuss with us. This will help us direct your inquiry to the right person at PCO.