Iron and steel

Our offer for iron and steelmaking industry

Although refractory materials represent a small fraction of the total cost of iron and steel production, their reliability is crucial for the efficiency of manufacturing processes.

Proper support in refractory technology can extend intervals between overhauls, reduce maintenance costs, and improve the process’s energy efficiency—helping to achieve sustainable development goals.Our mission is to support our partners in refractory technology exactly where their organizations need it most—from engineering studies, through joint selection of the most efficient material and installation solutions, logistics to any location worldwide, to on‑site installation or its supervision and post‑installation support. We believe that our reliable product quality and service, combined with comprehensive assistance, will minimize production downtime and enable our partners to become more competitive and sustainable through our refractory technology!

Discover our comprehensive offering for the iron and steel industry, encompassing a wide range of services and products: fireclay, andalusite, mullite, and high‑alumina bricks and castables, as well as thermal insulation.

What we can do for you

Design

- Thermal calculations using SimuTherm for selected zones of furnaces and ladles.

- Design of refractory linings for torpedo ladles, hotmetal ladles, blastfurnace hotblast

stoves, pushtype furnaces, and furnaces with retractable hearths (including

component drawings, material datasheets, bills of materials, installation instructions,

dryingcurve and commissioning instructions, and maintenance manuals). - Designs of prefabricated lining elements such as: EAF roof, burner blocks, taphole

blocks, electrode blocks, wall modules, arch modules, and hearth modules for

rollingmill furnaces.

Material supply

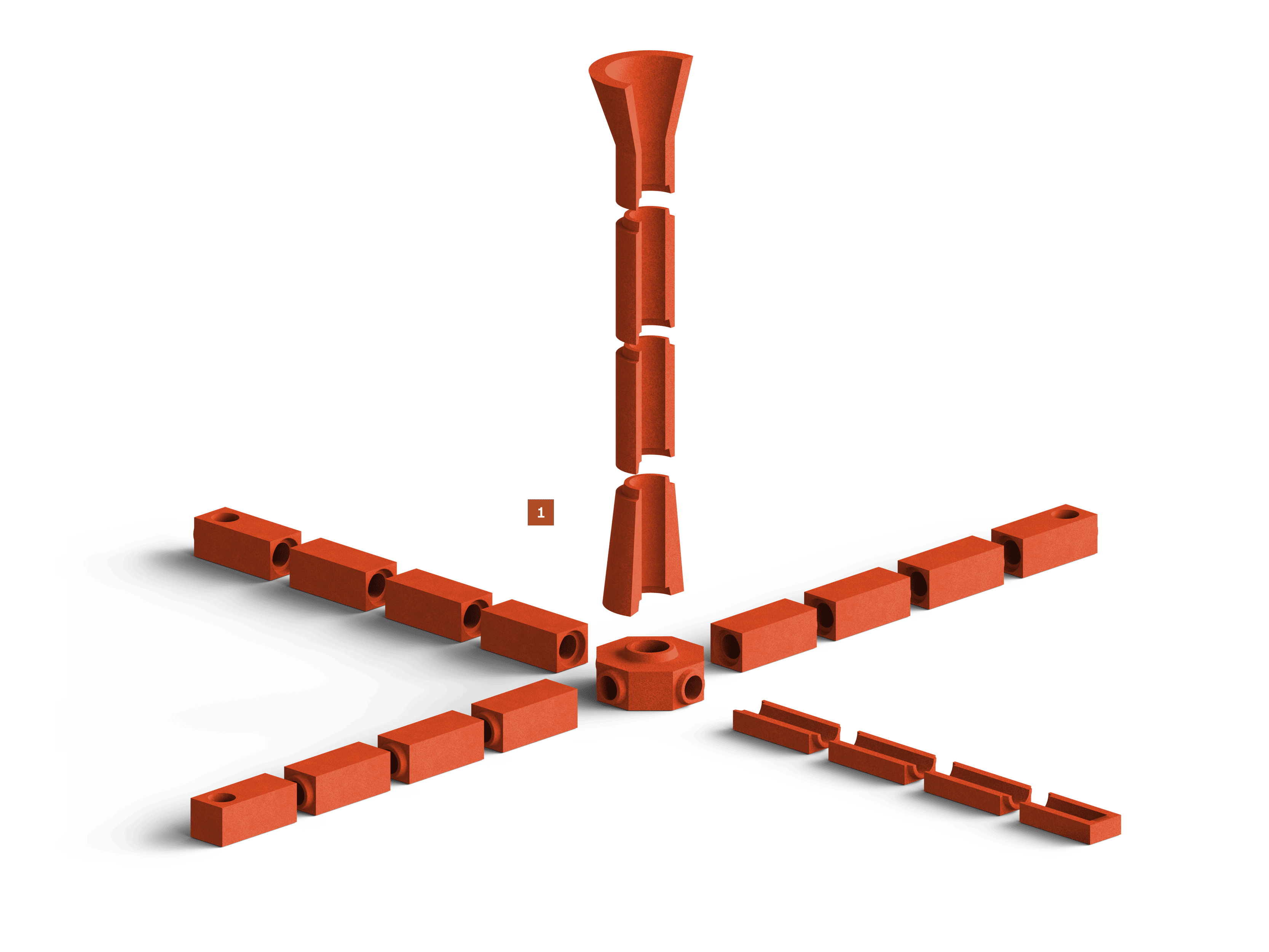

- Ceramic anchors with high thermal and mechanical strength in andalusite and bauxite

grades (60–85% Al₂O₃). - Large prefabricated cast elements—arches, partitions, and opening shapes—as well

as furnacecar trunnion blocks. - Funnel assemblies for siphon casting, produced by the semidry method on hydraulic

presses. - Insulating bricks and ceramic fiber mats for the insulating layers of furnaces and

ladles. - Refractory grid blocks in fireclay and highalumina grades for filling blastfurnace

hotblast stoves. - Refractory concretes (from conventional to ultralowcement) and insulating concretes,

plus repair mixes for hot repairs.

Installation services

- Planning and managing overhauls, including procurement of all necessary auxiliary

materials (formwork, steel components, consoles, fibrous insulation). - Dismantling and installation of ceramic linings for torpedo ladles, hotmetal ladles,

blastfurnace hotblast stoves, and rollingmill furnaces. - Technical consulting and supervision by experienced practitioners in ceramic masonry

and cast lining installation.

Furnaces and high-temperature industrial equipment

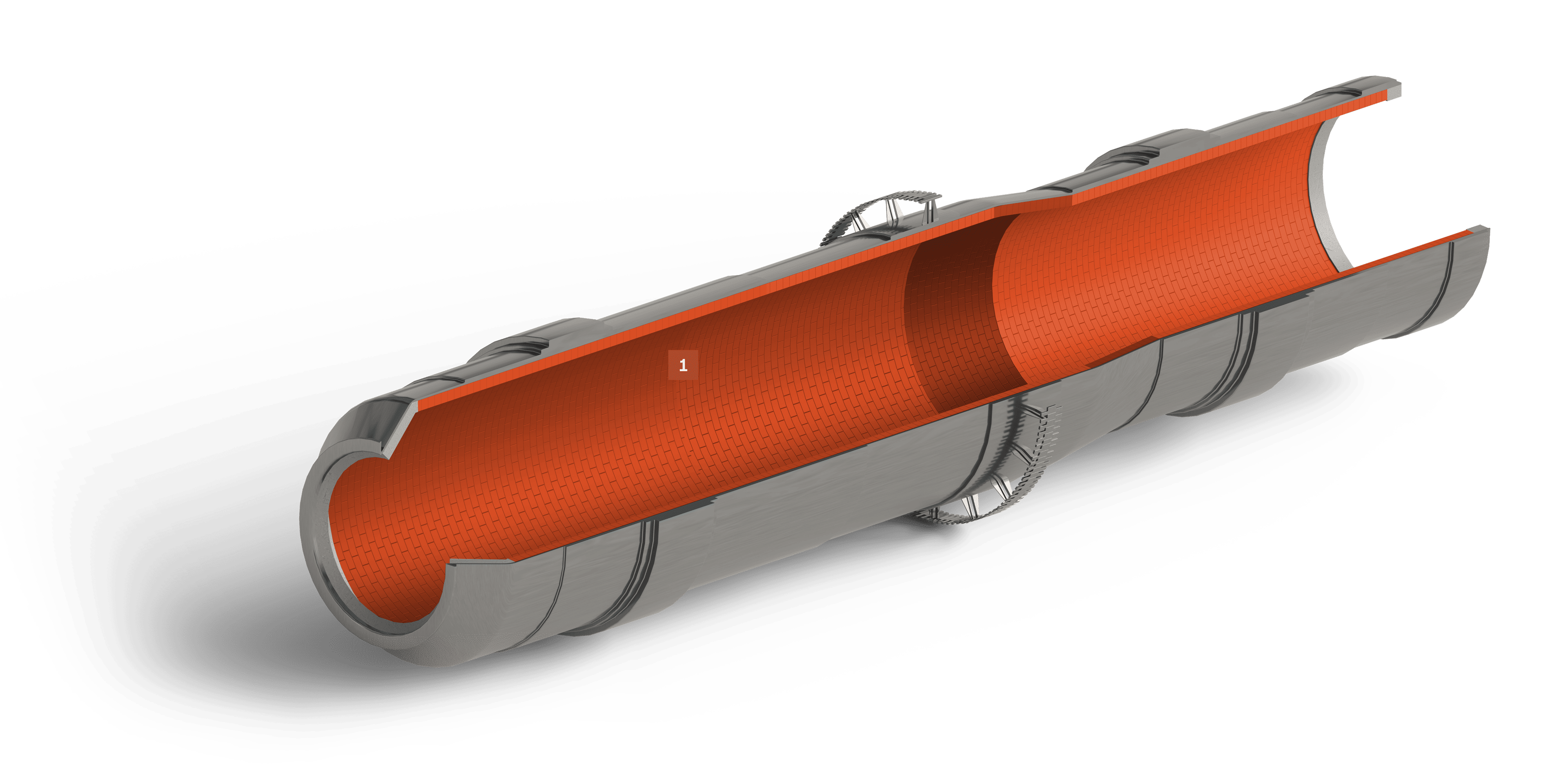

Iron-ore pellet grate kiln

The iron-ore pelletizing furnace enables the sintering of shaped iron-ore concentrate pellets. In the rotary kiln— the heart of the installation—three main zones can be distinguished: preheating, firing, and cooling. To ensure continuous, trouble-free operation, the refractory lining must combine strong resistance to thermal shocks, high abrasion strength, and excellent flexural and compressive strength (to withstand stresses from the kiln’s rotation and the pressure of the charge). PCO offers a range of chamotte and high-alumina materials in standard formats (ISO, VDZ) or custom designs. The largest pelletizing kilns for which PCO supplies refractories have an 8 m diameter. Downstream of the rotary kiln is the pellet cooler, which can be lined with castables, ramming mixes, or prefabricated elements ready for installation. Refractories used in this section are chosen for their thermal-shock resistance and abrasion durability.

Scope of offer: Lining design Refractory products supply Lining installation services

Most rotary kilns used for pelletizing employ high-alumina bricks, often containing 60–80% Al₂O₃. This composition is chosen for its ability to maintain high strength at elevated temperatures (typically up to 1400 °C in the firing zone) and for its excellent resistance to thermal shock and abrasion. Managing these hazards generally involves selecting well- designed interlocking bricks, ensuring high-quality installation with proper mortar and expansion joints, and—where feasible—using a composite lining system that incorporates an insulating layer to reduce thermal stresses.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryWhich material will reduce accretion from dust or ash and minimize spalling of lining fragments?

Which product will provide sufficient mechanical strength in a very large-diameter kiln?

How to protect the lining against the effects of steep temperature gradients from uneven heating and periodic cooling of the furnace?

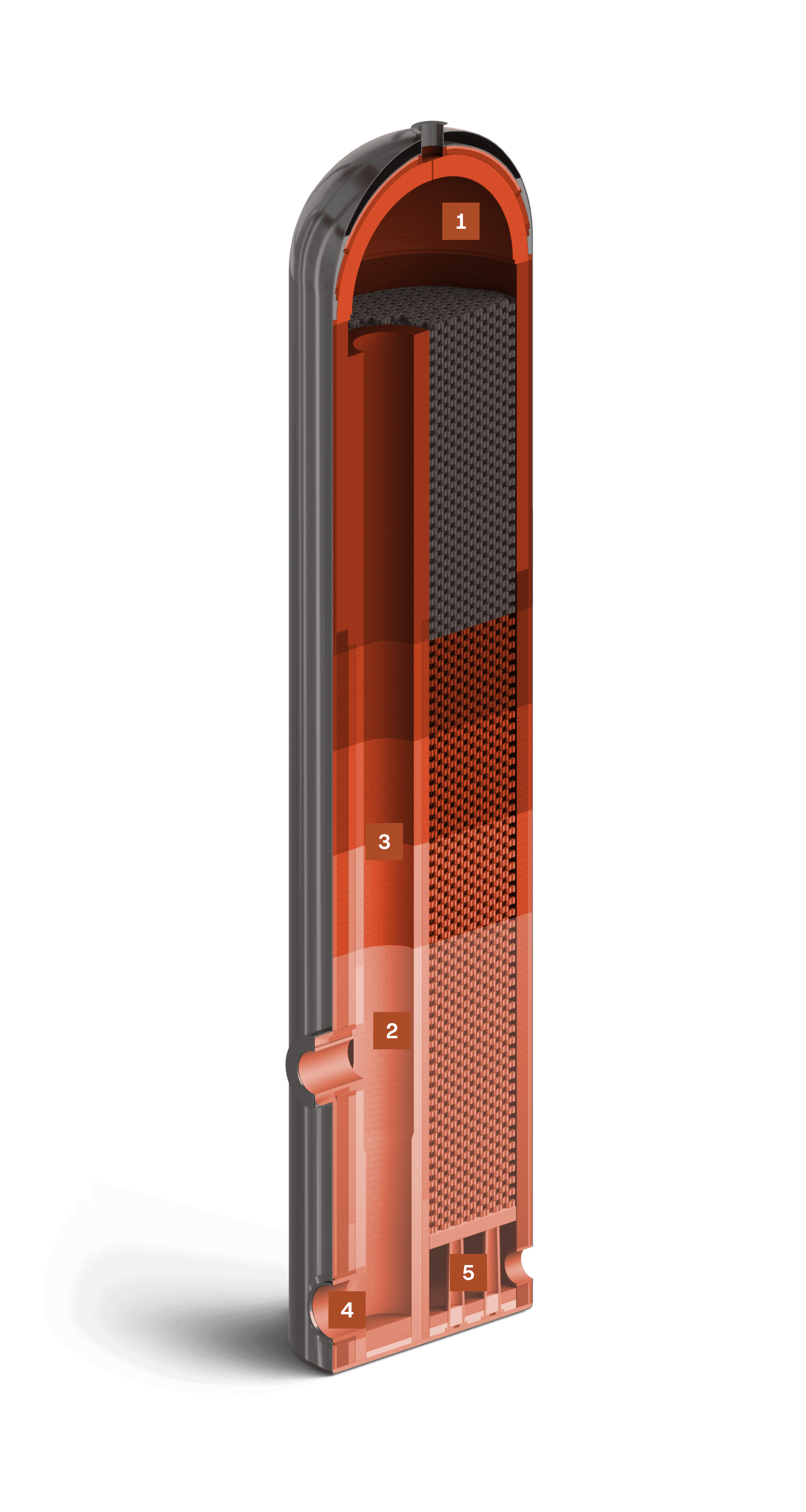

Hot-blast stove

The hot-blast stove in a blast furnace plays a key role in metallurgy by heating the charge to temperatures of up to 1000 °C. This process runs continuously, and its effectiveness depends on precise control of gas flow and uniform heat distribution. The refractory lining is exposed to rapid temperature changes, chemical corrosion from flue gases, and abrasion by fine charge particles, which necessitates the use of highly resistant materials. In the uppermost layers, silica grates are used, offering resistance to thermal deformation and chemical stability. In the lower sections, chamotte products are employed for their resistance to both high temperatures and intense mechanical wear, while andalusite elements in the higher zones provide dimensional stability and chemical resistance. Additionally, the insulating brick layers produced by PCO effectively minimize heat losses, enhancing the system’s energy efficiency and ensuring the installation’s reliability and longevity even under extreme industrial conditions.

Scope of offer: Lining design Refractory products supply Lining installation services

In the stove dome, where temperatures reach 1300–1400 °C, refractory materials must withstand intense exposure to both oxidizing and reducing atmospheres, heavy mechanical loads, and rapid temperature fluctuations that cause thermal shock and structural degradation. Ensuring lining durability requires the use of materials with a high degree of mullite formation, such as ANDALUX products, which offer dimensional stability, low porosity, and corrosion resistance. Precise material selection is critical for system reliability and for maximizing the efficiency of the process.

In this section of the hot-blast stove, refractory materials must withstand extreme temperatures, aggressive chemical atmospheres, and severe thermal shocks. High-mullite-content products, such as ANDALUX, are critical for ensuring dimensional stability under intense thermal loads. In slightly lower-temperature areas, SUPERTON is employed; its high mechanical strength guarantees the lining’s durability. Additionally, ISOLUX materials minimize heat losses, enhancing energy efficiency and extending the stove’s operational life.

Grate elements in the regenerator zone play a key role in the heat-exchange process, enabling the efficient preheating of air directed to the blast furnace. The materials used in this section of the hot-blast stove must exhibit exceptional resistance to high temperatures, aggressive gas atmospheres, and mechanical loads. Depending on the specific zone, chamotte or andalusite grate elements are employed to ensure long-term durability and structural stability.

Burners deliver thermal energy to the hot-blast stove system, necessitating the careful selection of refractory materials. Their role is to ensure long component life, high energy efficiency, and overall process safety. Under dynamic operating conditions, mullite refractories are most commonly used, as they combine resistance to rapid thermal shocks with the ability to sustain high temperatures. Proper selection of mullite products minimizes the risk of material degradation, thereby enhancing process stability and the reliability of the hot-blast stove system.

Ducts are conduits that transport very hot air from the hot-blast stove to the blast furnace. They operate under high temperatures, dynamic thermal fluctuations, and in an aggressive chemical environment, making the selection of resistant refractory materials essential. In moderate-temperature zones, chamotte is used for its cost-effectiveness, whereas in areas subject to rapid temperature changes, mullite products are employed to ensure system stability and reliability.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryHow should grate elements be designed to minimize regenerator fouling and slag buildup?

Which material will protect burners against spalling and thermal-shock damage?

How can expansion joints be implemented in a ceramic lining to accommodate permanent dimensional changes after heating and cooling?

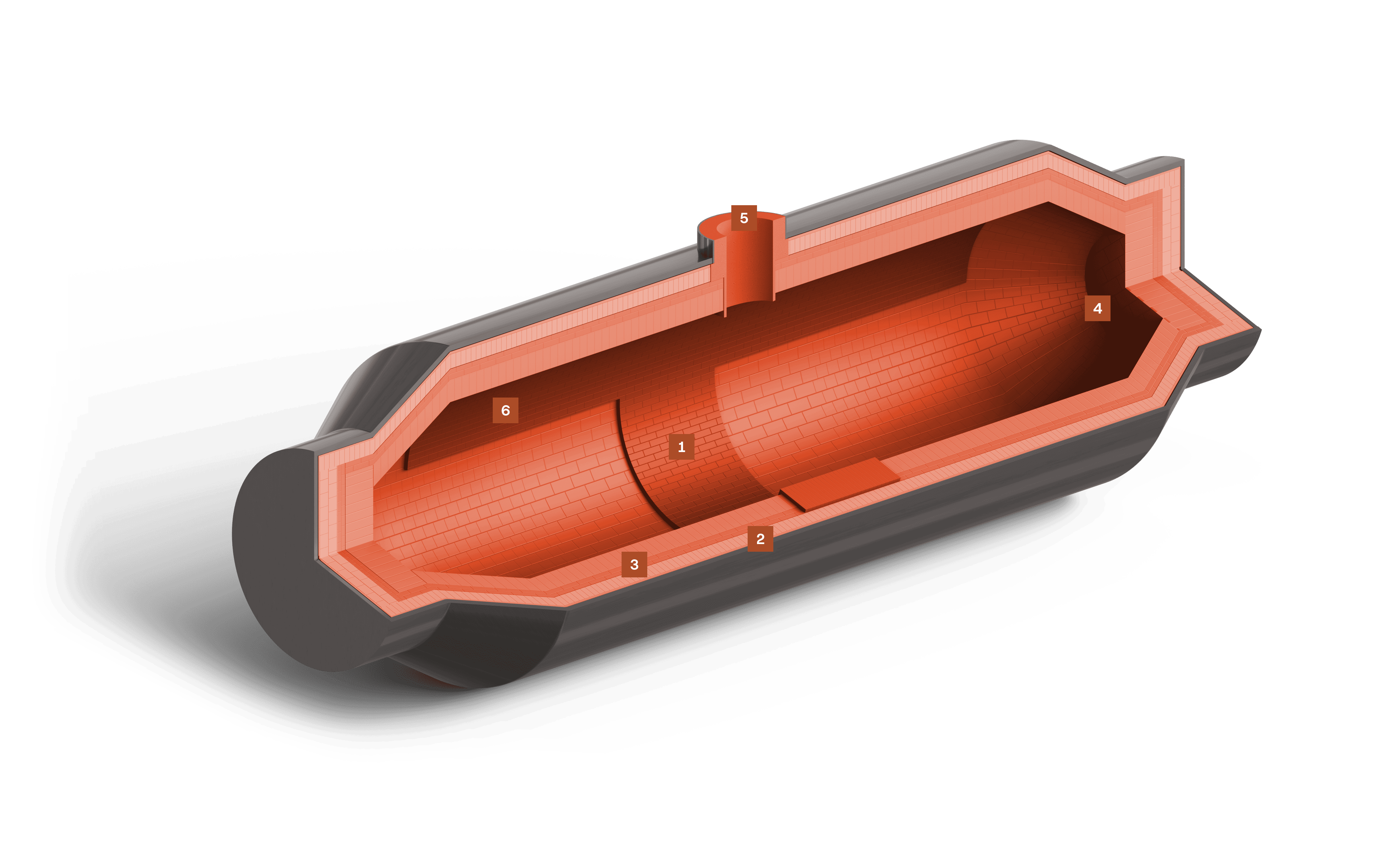

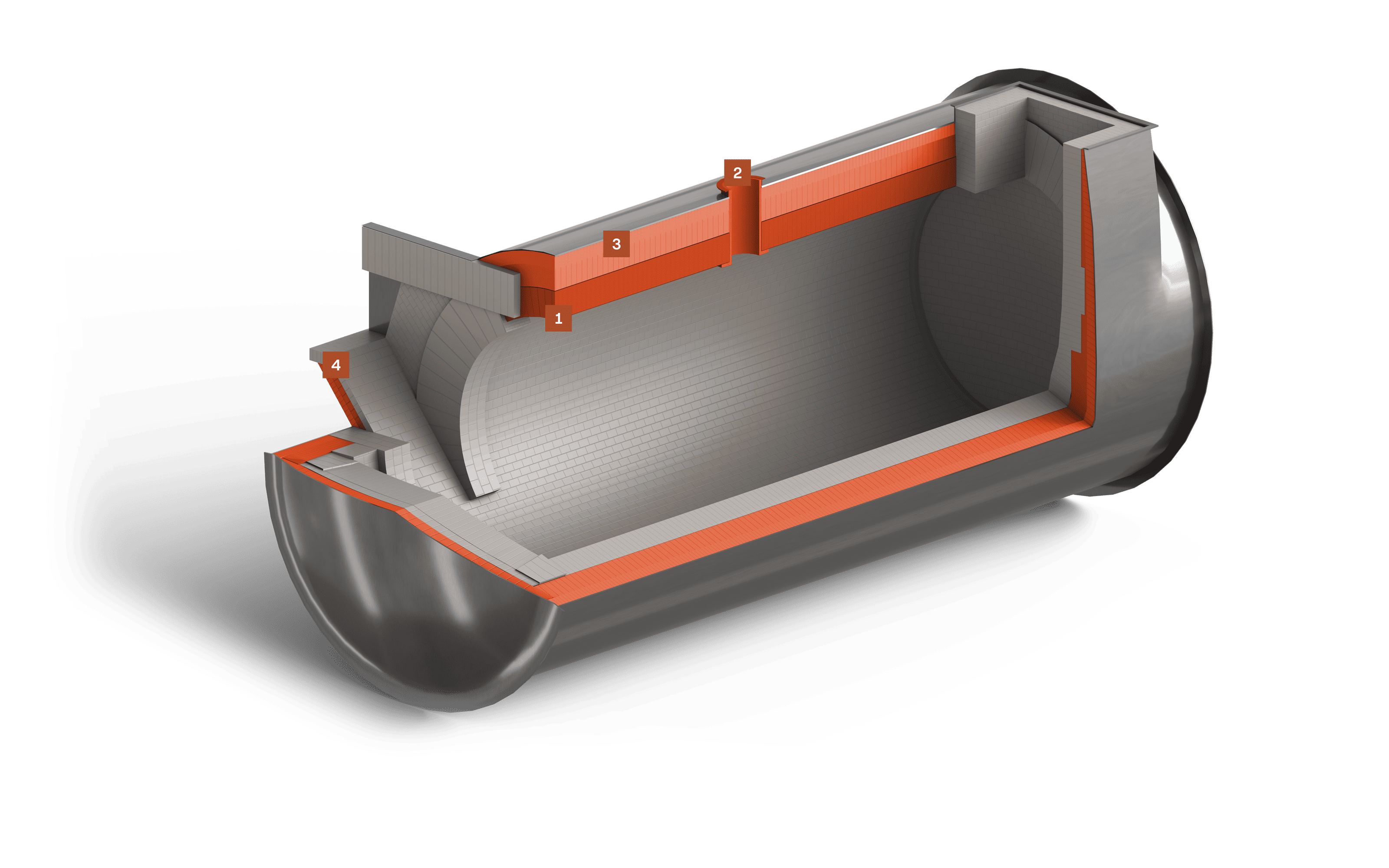

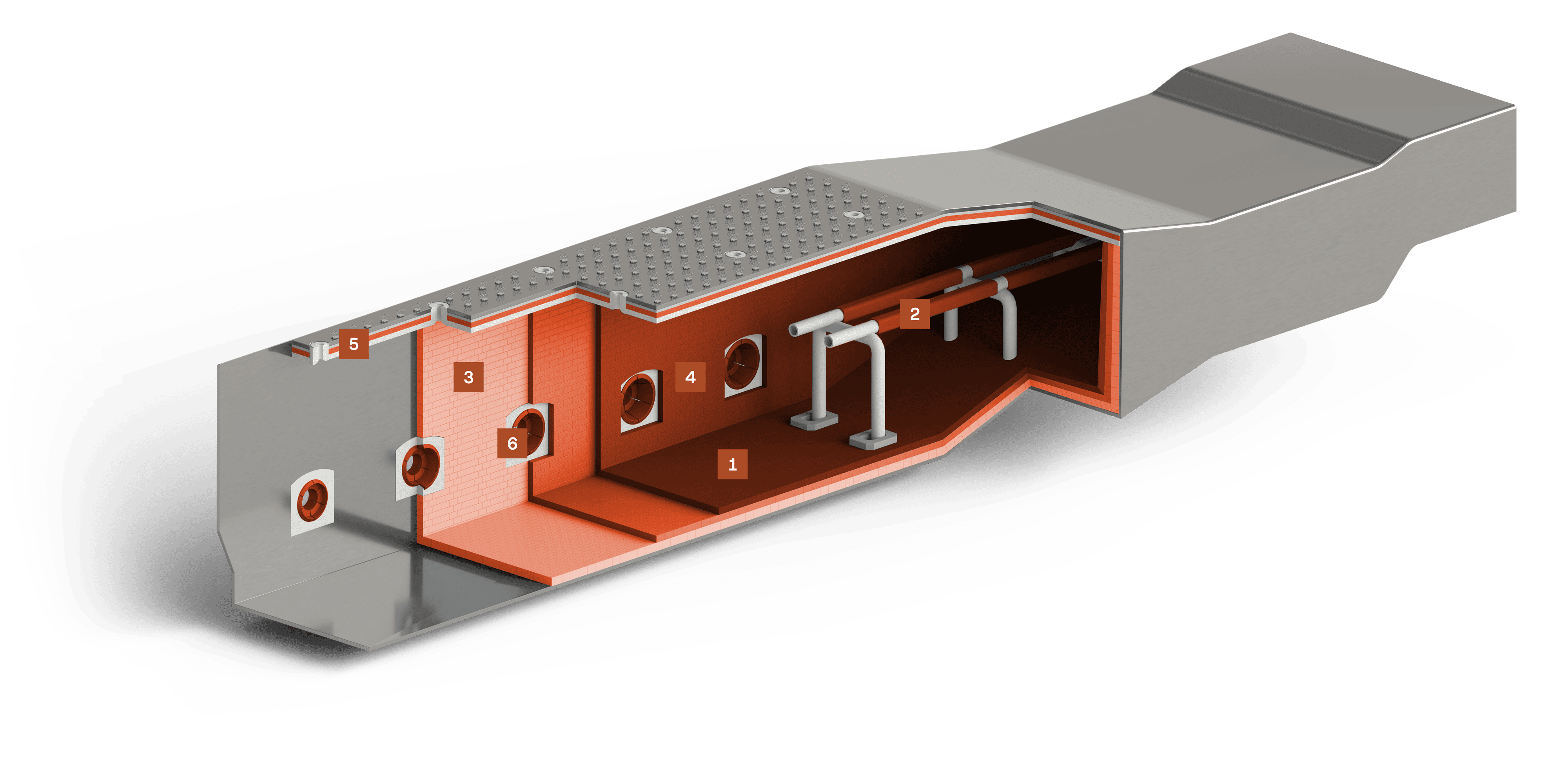

Torpedo Ladle

The torpedo ladle, used for transporting molten steel from the converter to casting stations, must withstand extreme thermal conditions, as molten steel temperatures often exceed 1600 °C. These vessels have a large capacity—from about 200 up to 460 tons—and operate in a rapid cycle of filling, transport, and pouring, which generates abrupt temperature fluctuations and dynamic mechanical loads. The refractory lining of the torpedo ladle is designed to minimize heat losses, resist thermal shock, and withstand aggressive chemical compounds present in the molten steel. Special attention is given to erosion caused by the action of hot metal and slag. PCO Żarów offers a complete range of refractory materials for lining torpedo ladles, covering both protective and working layers. The portfolio includes refractory concretes and prefabricated elements used in the most demanding areas, such as the throat and impact zone.

Scope of offer: Lining design Refractory products supply Lining installation services

The impact zone of the torpedo ladle is the area where molten steel violently strikes the lining, generating extreme thermal and mechanical shocks. The refractory materials used in this zone must exhibit very high thermal resistance and the ability to absorb large heat pulses without structural damage. A crucial aspect is maintaining lining continuity even under intense impacts, which minimizes the risk of degradation from sudden loading spikes. Products specified for this area ensure the structural stability of the torpedo ladle under extreme heat impulses, which is essential for the long-term, reliable operation of the vessel.

The insulating layer of the ladle lining protects the structure from heat losses and deformation caused by transporting large volumes of hot metal. In practice, a multilayer system is used, combining refractory boards or bricks with insulating properties and mineral wool insulation blankets. This arrangement creates a unified thermal and mechanical barrier, minimizing the risk of lining deformation. It is recommended to use materials that offer both good thermal insulation and high compressive strength. PCO’s portfolio includes PERLITEX and ISOLUX grades, which meet these requirements by effectively reducing heat losses and ensuring structural reliability during hot metal transport.

The protective layer of the torpedo ladle, like the transition layer, is designed to shield the lining from direct contact with molten steel and slag, which can cause intense chemical attack and abrasion. In the event of working layer failure, the protective material must effectively safeguard the entire structure from degradation. NORMATON, SUPERTON, or ANDALUX bricks are used, which can also serve as a transition layer. The material chosen for the protective layer must feature high thermal insulation, resistance to abrasion and contact with molten steel and slag, as well as good compressive strength to prevent deformation should the working layer fail.

The working layer of the torpedo ladle, in direct contact with the molten steel, is the most exposed to aggressive process conditions and the erosive action of liquid metal and slag. Extreme thermal shocks, intense chemical attack, and abrasion require the use of materials with very high resistance while maintaining precise dimensional accuracy. Torpedo ladles, due to their shape and years of service, can deform, making tight tolerance control of the working-layer shapes critical to minimizing the risk of “peening” (localized protrusions). In some installations, a transition layer is laid immediately behind the working layer, providing a graded interface to the protective layer. This arrangement allows compatibility between materials with differing thermal and mechanical properties, ensuring long-term structural stability of the torpedo ladle.

The throat of the torpedo ladle is the passage through which molten steel is poured and drained during transport from the blast furnace to the hot-metal ladle. Its complex geometry and the intensity of thermal and mechanical stresses demand dense refractory concretes that create a homogeneous, robust structure capable of withstanding violent metal flows. PCO Żarów offers a range of high-performance refractory concretes for this application, featuring outstanding thermal and erosion resistance. Among the recommended solutions are “fast-dry” concretes, which allow rapid drying at relatively low temperatures—an important advantage over conventional refractory mortars.

The slag zone in a torpedo ladle is the area where residual slag and ashes accumulate. Temperatures here are milder, but increased friction generates additional mechanical loads that can lead to secondary reactions of carbonates. The lining material used in this zone must exhibit high abrasion and friction resistance to provide long-term protection of the structure. Although specific solutions can be tailored to each installation’s requirements, chosen products must guarantee sufficient mechanical strength even at lower temperatures and under elevated friction, ensuring the stability and durability of the torpedo ladle lining.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryCorrosion of the lining in the slag zone: Which material will be most resistant to the effects of blast-furnace slag?

Layer configuration: Which multilayer lining system will best protect the ladle ceramics against thermal shock during filling cycles?

Material selection for the impact zone: How should you choose a material to minimize lining degradation in the impact zone?

Pig iron ladle

The hot metal ladle, used in ironmaking processes, serves a key role as a vessel for transporting and storing molten iron (“hot metal”) at temperatures around 1400–1500 °C. The transportation process—operated continuously or cyclically—requires precise control of thermal and mechanical parameters to ensure the quality and chemical composition of the metal. The refractory lining of the ladle must withstand intense thermal loads, thermal shocks during filling and emptying, aggressive flue-gas atmospheres, and the presence of slag. Selecting refractory mixes with high corrosion and abrasion resistance is critical for long-term service in these harsh conditions. PCO Żarów offers complete linings for hot metal ladles, covering both the working and protective layers. In the zones in direct contact with molten iron, we use specialized refractory bricks, while the ladle’s sidewalls are protected with refractory concretes. For the insulating layer, we recommend insulating bricks and lightweight insulating concretes, which provide efficient thermal insulation and minimize heat losses.

Scope of offer: Lining design Refractory products supply Lining installation services

In this zone, the material must not only exhibit high refractoriness but also resist corrosion and erosion caused by molten steel and slag. The intense operation of the ladle, along with the possibility of mechanical compaction during transport, places additional stress on the rim structure. To meet these demands, PCO Żarów offers low- and medium-cement refractory concretes that can be applied either by casting or by spray. For ease of ladle construction, the material used for the rim is identical to that used on the ladle’s pour spout.

The protective and insulating layer of the hot metal ladle plays a key role in reducing heat losses, enabling the molten steel to maintain its optimal temperature over extended periods. PCO Żarów offers comprehensive insulation solutions, utilizing both dense refractory bricks and specialized refractory concretes. The proposed materials feature high resistance to extreme temperatures and aggressive service conditions, ensuring a long service life for the ladle. Selecting the appropriate insulating layers allows precise adaptation of properties to the specifics of each process, minimizing energy losses and optimizing operating costs.

Due to its application, the working ceramic lining of the hot metal ladle is subject to deformation, so it is essential that the supplied shapes have extremely tight dimensional tolerances. Equally important is matching the thermal expansion of the refractory products to prevent joint washout under cyclic temperature changes. Materials used in the working layer must withstand extreme service conditions—high temperatures, rapid thermal shocks, and the aggressive action of molten steel and slag. Properly selected refractories ensure not only resistance to corrosive and erosive effects but also the structural stability of the ladle lining, which is critical for maintaining optimal process parameters and final product quality.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryHow can you protect an aluminosilicate lining against the aggressive effects of basic slag?

Which multilayer lining configuration will minimize thermo-mechanical cracking in the working lining?

Which refractory concrete will provide erosion-resistance for the ladle rim and pour spout?

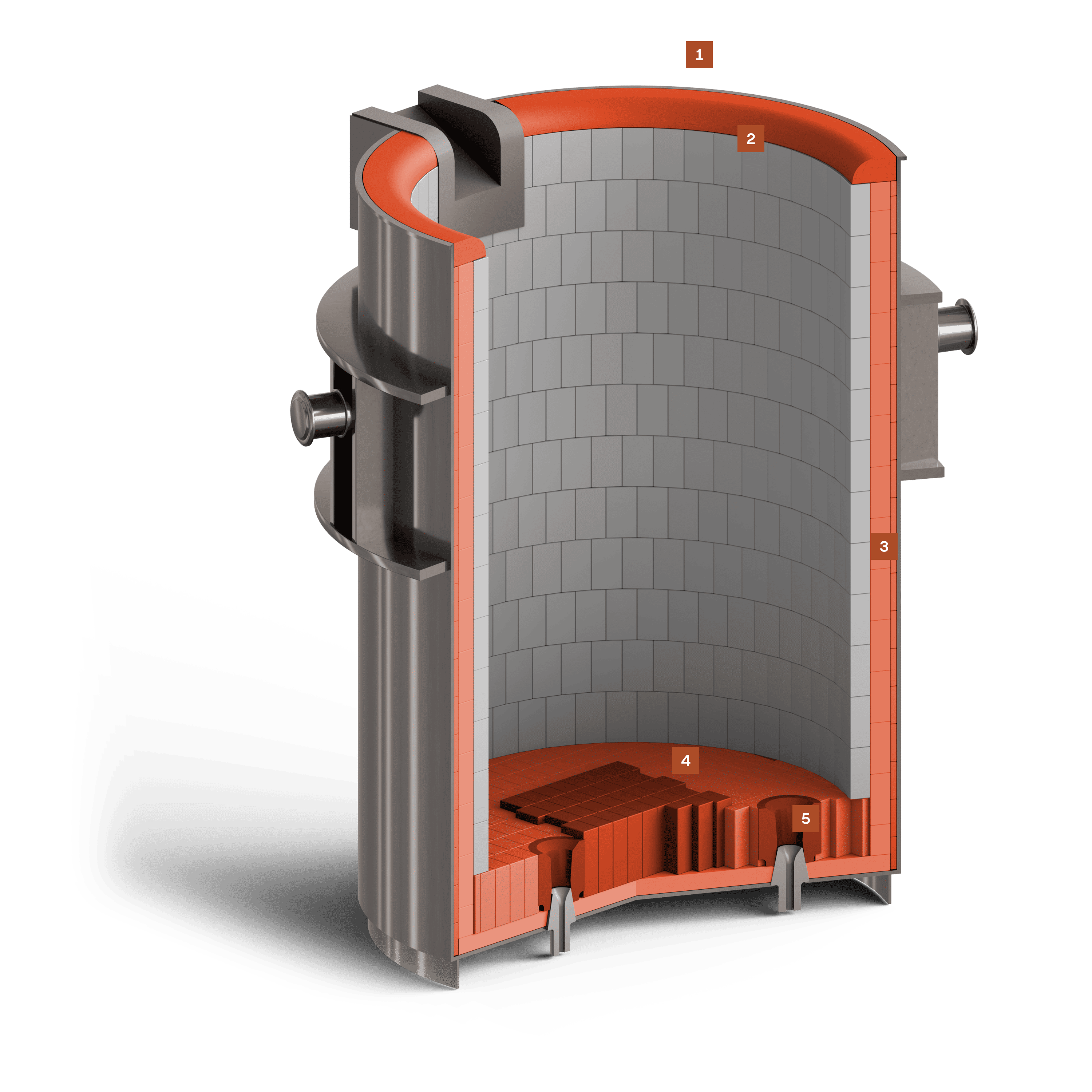

Hot metal mixer

The hot metal mixer serves to store (buffer) and homogenize blast-furnace hot metal in the steel plant while maintaining its required properties—primarily temperature. The mixer’s refractory lining operates at extremely high temperatures, around 1400–1500 °C, and must resist temperature fluctuations, chemical corrosion, and erosion from the flow of liquid metal. Selection of refractory materials depends on the specific zone of the mixer, since different areas are subject to distinct types of load. PCO products are used both in the working lining of the upper zone and in the insulating layers beneath the main lining, ensuring optimal protection and long service life. PCO Żarów supplies cast linings for the burner block and the mixer’s pour spout. For the upper cylindrical zone—which does not come into direct contact with metal—we provide high-alumina andalusite bricks.

Scope of offer: Lining design Refractory products supply Lining installation services

The metal zone includes the upper sections of the cylindrical part, the side walls, and the filling port. In this area, the lining is subjected to severe thermal shocks and erosive wear from the flow of molten steel. High-alumina aluminosilicate materials such as ANDALUX deliver excellent resistance to thermal shock and erosion, ensuring that the lining in the metal zone retains its properties even under intense exposure to liquid steel.

In the burner zone, refractory materials face heavy mechanical wear and aggressive chemical attack. To meet these demands, PCO Żarów recommends PCOCAST BN X222, a low-cement concrete characterized by very high strength at elevated temperatures, remaining stable even at temperatures up to 1600 °C.

The primary function of the insulating layer is to minimize heat loss and protect the mixer’s steel shell from excessive heating. This layer employs both chamotte products with 42–44 % Al₂O₃ (such as SUPERTON) and lightweight insulating bricks from the ISOLUX series. This combination achieves high thermal insulation while maintaining compressive strength and thermal stability.

The spout is the terminal section of the mixer, where refractory materials are exposed to high temperatures, rapid thermal shocks, and intense mechanical and chemical wear—just as in the burner zone. In this location, the material’s resistance to direct contact with molten steel and slag is critical. PCO Żarów recommends the use of PCOCAST BN X222 concrete, which retains its properties even at temperatures up to 1600 °C.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryHow should you select the protective‐layer material that best withstands thermal stresses during operating cycles?

Which materials will resist deformation and creep due to mechanical loads when the mixer rotates?

How can you integrate an aluminosilicate lining with a basic (alkaline) working lining in the upper metal zone?

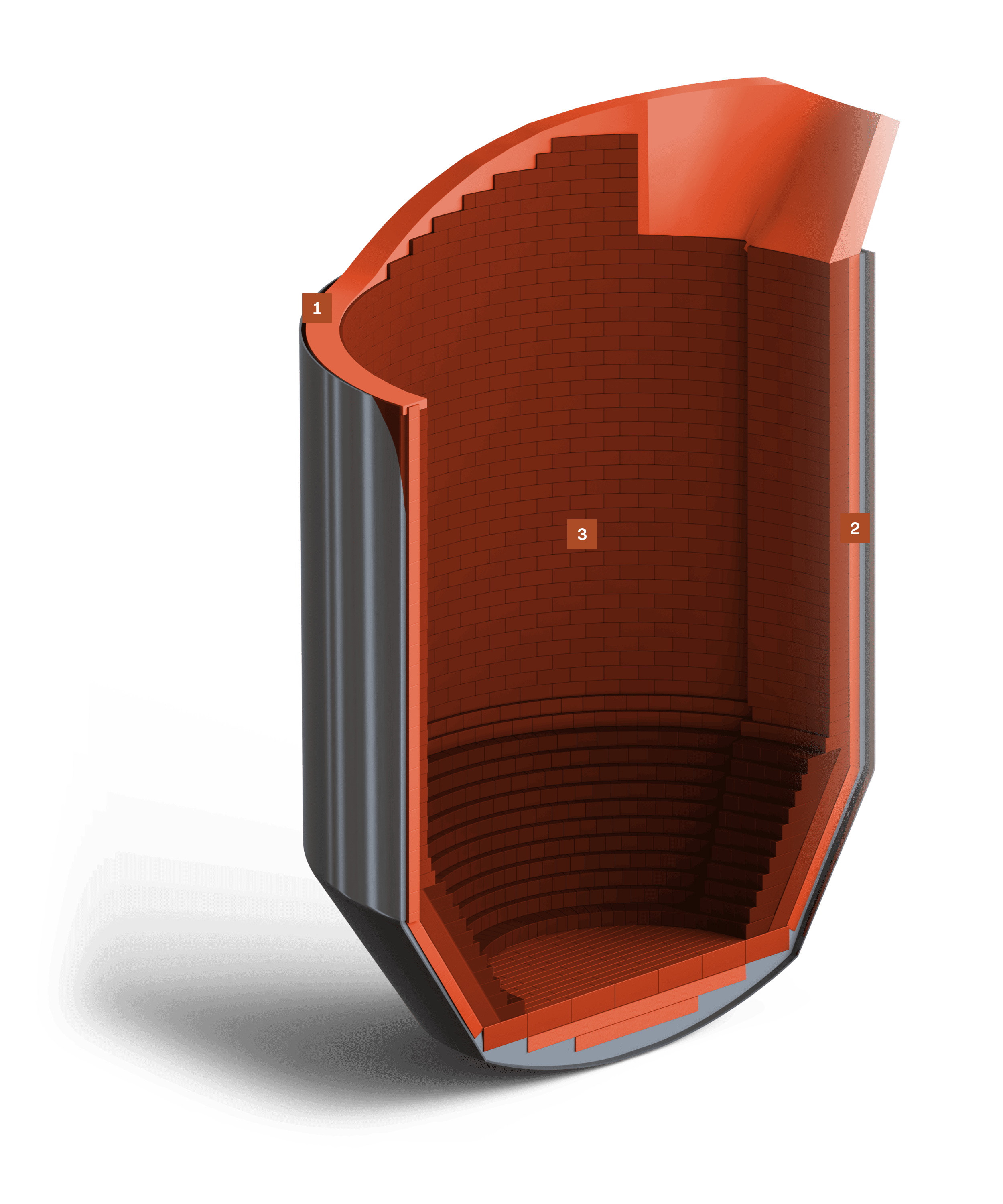

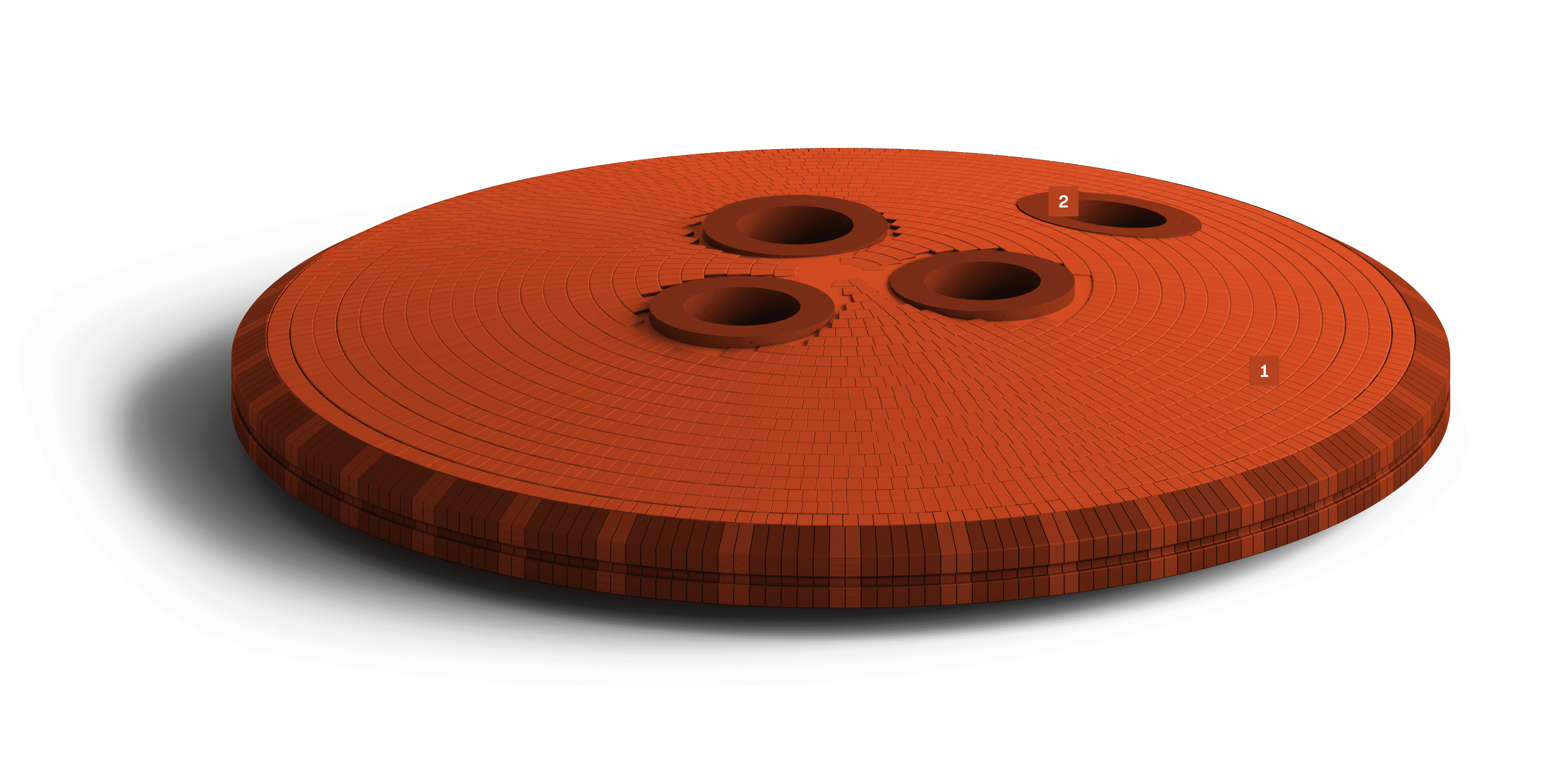

Electric Arc Furnace roof

The roof of an electric arc furnace (EAF) forms the internal, dome-shaped part of the structure that directly surrounds the electric arc zone, where temperatures can soar to 1600 °C and beyond. Its primary functions are not only to protect the furnace shell but also to ensure even heat distribution and minimize thermal losses during intensive operating cycles. The furnace charge is directly exposed to the electric arc, and current from the electrodes passes straight through the charge material. Wear of the refractory lining in an electric arc furnace is much more rapid than in other steel-making thermal units.

Scope of offer: Lining design Refractory products supply Lining installation services

To extend the service life of this critical component, we have developed special PCOCAST refractory concretes—such as 170KCR5 and BNX222. Thanks to advanced technology, these concretes resist frequent and rapid temperature fluctuations, ensuring structural stability of the dome. An additional advantage of our solutions is an optimized setting time, which allows casting and initial drying “in situ” on-site at the steel mill.

Electrode-entry shapes surround the openings through which graphite electrodes enter the furnace. These shapes allow the electrodes to move safely (raise and lower) during furnace operation and keep the electric arc correctly positioned within the melting chamber. For these shapes, we recommend high-alumina bricks and low-cement concretes containing over 80% Al₂O₃.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryHow should you design the dome to achieve maximum resistance to sudden temperature increases and prevent spalling of the lining?

Which material will best resist corrosion from condensable vapors on the dome?

How do you design and install the electrode-entry shapes to prevent cracking from vibrations and electrode movement?

Main ladle

The main ladle, used for transporting molten steel during melting and subsequent processing, operates at temperatures between 1550–1650 °C and undergoes intense thermal cycling. Its primary function is to maintain the stability of the transported metal while minimizing heat losses—crucial for preserving the steel’s optimal chemical parameters. The refractory lining of the steelmaking ladle must withstand rapid temperature fluctuations, mechanical stresses, and chemical corrosion caused by molten-metal constituents and combustion by-products. PCO Żarów supplies dedicated refractory products for the ladle shell and protective wall layers, using magnesia-based bricks in the working lining. The ladle floor lining—including the working layer and the pour-spout shapes—can be constructed from unfired aluminosilicate products, ensuring durability and structural stability under extreme operating conditions.

Scope of offer: Lining design Refractory products supply Lining installation services

The ladle cover is responsible for maintaining the molten steel’s high temperature during transport. To meet these demands, it must not only resist extreme temperatures but also provide excellent insulation. PCO Żarów has developed a specialized concrete grade that, despite its high temperature resistance, offers superior insulating properties compared to standard concretes of the same class. Using this material allows the ladle to retain optimal steel temperature while reducing cover weight and concrete consumption thanks to its lower density.

The lip ring of the main ladle is exposed to intense contact with molten steel, slag, and mechanical compaction during transport. Refractory materials used in this zone must combine exceptional resistance to high temperatures, aggressive chemical attack, and dynamic mechanical loads. PCO Żarów offers a range of refractory concretes—low-cement, ultra-low-cement, or no-cement formulations—designed with high-quality aggregates to meet these requirements.

The protective layer of the ladle plays a crucial role in reducing heat losses, enabling prolonged maintenance of the molten steel’s temperature. Effective interior insulation minimizes heat loss, improving tapping efficiency and delivering energy savings. PCO Żarów provides both dense refractory bricks and refractory concretes for this layer. Both solutions deliver high insulating performance while ensuring resistance to dynamic mechanical stresses.

The working lining of the steelmaking ladle bottom is a critical element that comes into direct contact with molten steel and slag materials. In this zone, it is essential to ensure uniformity and continuity of the ceramic lining structure. To meet these requirements, PCO Żarów has engineered a specially chemically bonded product dedicated to the impact pad area. Additionally, for the walls of the working layer in the metal and slag zones, we offer ANDALUX and BAUXITEX family products, which guarantee high resistance to molten steel and slag, contributing to the long-term stability of the lining.

Nozzle shapes perform one of the most demanding functions in the ladle – they protect and guide the flow of molten steel. Due to the extreme service conditions, the raw materials used to produce these shapes must exhibit very high purity as well as chemical and thermal stability. PCO Żarów has developed several grades of spinel-bonded concretes dedicated to shell-shape fabrication. These products feature outstanding resistance to corrosion and erosion by molten steel, minimizing the risk of lining degradation even after prolonged use.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryErosion of the ladle bottom lining: how should one design the so-called “impact pad” and minimize wear of the shell shapes?

Which products will best protect the protective layer from cracking and spalling due to thermal shock?

How can you determine the need for a lining overhaul based on ceramic wear in the slag zone?

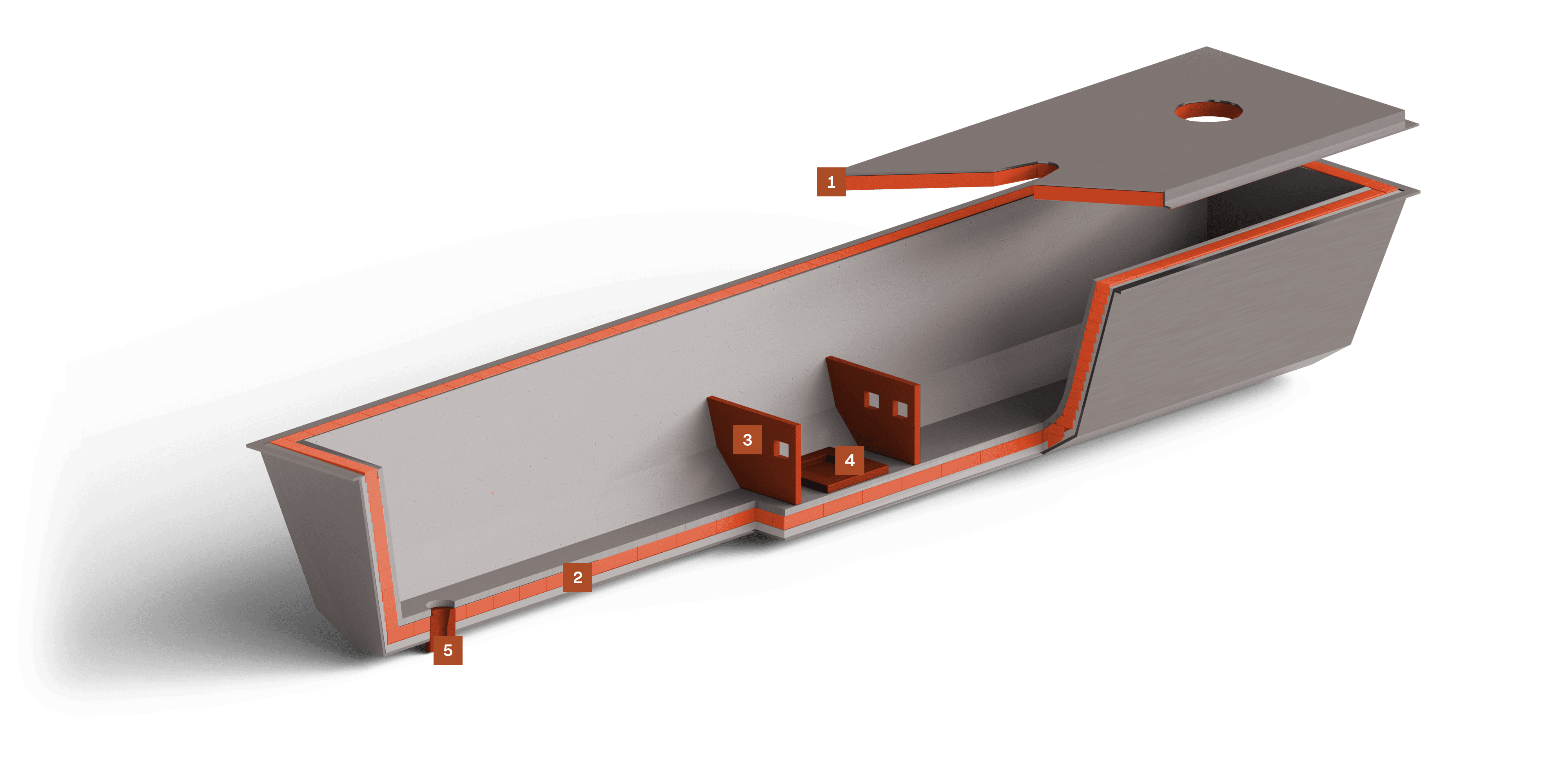

Tundish

The tundish plays a key role in the continuous casting system. Its primary functions are to buffer and distribute molten steel—ensuring process continuity during a ladle change—and to homogenize the temperature and chemical composition of the metal through its carefully engineered internal lining. The refractory lining must offer high resistance to thermal shock, intense chemical erosion from liquid steel contact, and abrasion caused by steel flow. Precise control of process parameters and the proper selection of refractory materials are therefore essential for reliable tundish operation. PCO Żarów supplies all necessary working‐layer components, including the cover lining, prefabricated partitions, under‐stream plates beneath the pour, and shell shapes in the metal outlet zones.

Scope of offer: Lining design Refractory products supply Lining installation services

The tundish cover is responsible for maintaining the molten steel’s high temperature by minimizing heat losses. To meet these demands, PCO Żarów offers high-alumina concretes which, despite their excellent temperature resistance, also provide enhanced insulating performance. By using these products, it is possible to keep the steel at its optimal temperature while reducing the cover lining’s mass (thanks to lower density and thus less concrete). These properties translate into improved thermal efficiency of the tundish and optimized operating costs.

The protective layer of the tundish lining primarily serves to reduce heat losses. PCO Żarów supplies dedicated solutions for this layer, including insulating bricks such as ISOLUX, known for their high thermal insulation, and dense bricks like ANDALUX and BAUXITEX, which offer the necessary mechanical strength and resistance to aggressive attack by molten steel and slag (in the event of working-layer penetration). Refractory concretes of the PCOCAST and MULCAST classes ensure uniform installation fill—thanks to excellent flow characteristics—eliminating gaps and further enhancing insulation.

Tundish partitions are designed to eliminate turbulence during ladle filling, thereby reducing inclusions and improving metal homogenization. In this zone, the lining is subjected to both corrosive and erosive attack from molten steel and slag, making the selection of highly resistant refractories critical. PCO Żarów’s products feature superior refractoriness and effective resistance to these aggressive conditions, ensuring long-lasting partition integrity and minimizing the risk of damage during intensive filling operations.

Impact pad protect the ladle from steel breakthrough. Because of the intense exposure to molten steel, these plates must be manufactured with utmost precision, ensuring a uniform structure and high resistance to thermal and mechanical shocks. PCO Żarów offers plates produced by dry pressing as well as cast from refractory concrete. These innovative solutions—proven under steelmaking conditions—provide continuous protection for the ladle lining while extending its service life.

Nozzle shapes, which come into direct contact with molten steel, must exhibit excellent thermal strength, shock resistance, minimal material shrinkage, and precise manufacturing to guarantee a tight seal at the pour spout. PCO Żarów supplies a broad range of pressed shell shapes, including products from the ANDALUX and BAUXITEX families, as well as prefabricated elements such as PCOCAST and MULCAST. These offerings ensure reliable performance and durability in the most demanding applications.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryWhich working lining will best withstand thermal shock during the first pour of molten steel?

How should tundish partitions be designed to resist abrasion, corrosion, and material washout?

Which material should be chosen to avoid metal contamination from ceramic lining inclusions?

Ingot casting system

The ingot casting system is an integral part of the siphon‑casting line for steel, consists of a series of ceramic components that enable the precise distribution of molten metal into the molds. These components operate at very high temperatures (often above 1600 °C) and are subjected to rapid changes in flow and pressure. The refractory materials used in the funnel assembly must resist intense thermal loads, sudden heating and cooling cycles, and chemical corrosion from the aggressive environment of molten metal. The contact surface between the liquid metal and the ceramic parts is critical: it must not release contaminants (inclusions) and must allow for easy separation from the metal once casting is complete. A precise match of material solutions to the process conditions—especially the type of steel being cast—ensures optimal technological parameters and guarantees high casting quality.

Scope of offer: Lining design Refractory products supply Lining installation services

PCO supplies complete funnel assemblies with varying throughputs. Owing to our manufacturing method (dry pressing of semi-dry mix), the thinnest walls in our available shapes are 20 mm thick. We produce the assembly shapes by dry pressing, which allows us to create highly precise features—such as inlets and outlets, tubes, channels, and the distribution plate—guaranteeing perfect mutual fit.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryWhich material will deliver the highest thermal-shock resistance during the pour?

How should the dimensions of the funnel elements be designed to minimize erosion and abrasion of the tubes and channels?

Which material will minimize interaction with the steel and protect the assembly from unwanted inclusions?

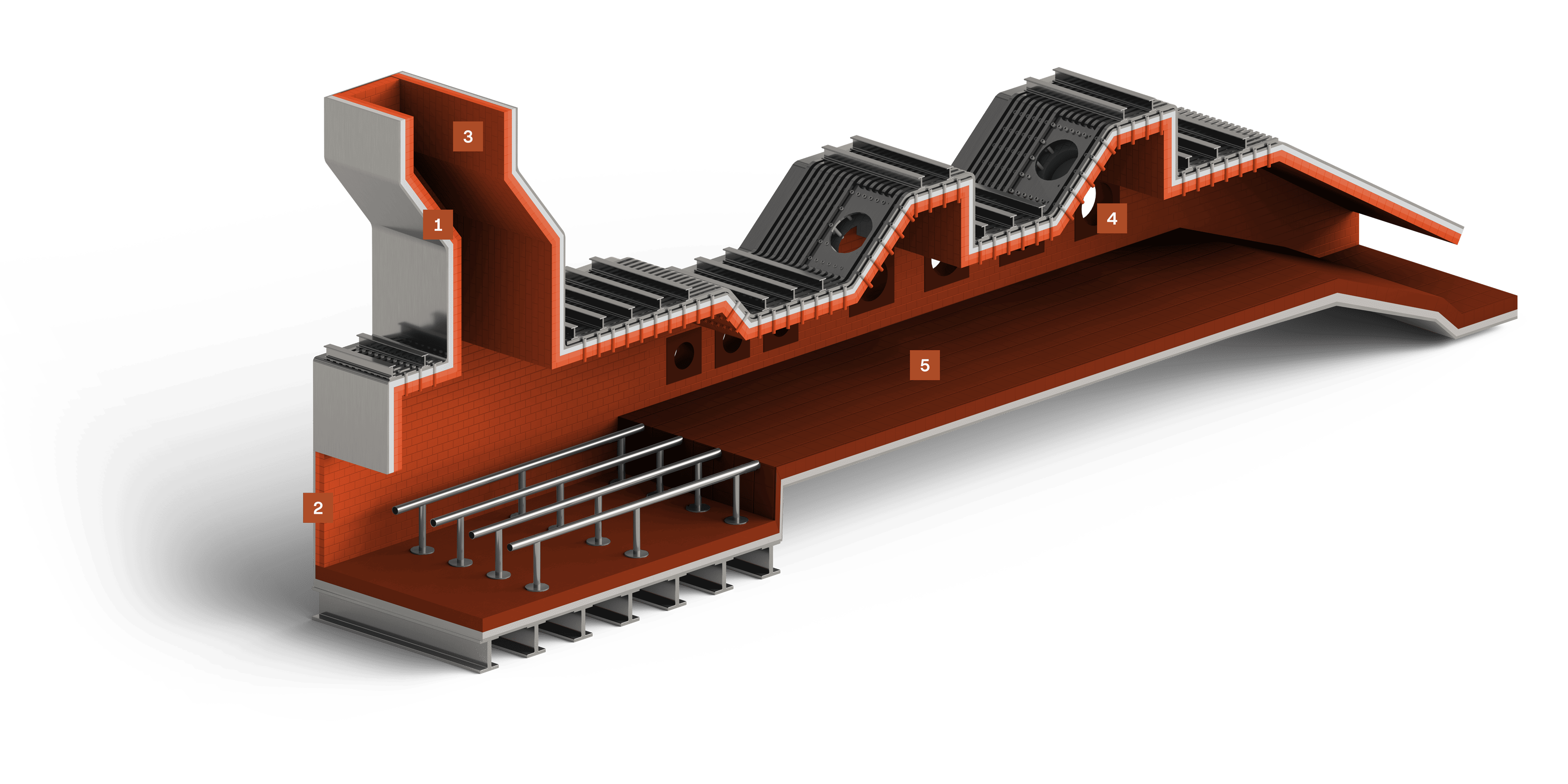

Pusher type furnace

The pusher furnace is used to heat steel prior to further hot‐working processes such as rolling or forging. These furnaces feature distinct zones—preheating, heating, and equalizing. For efficient, long‐lasting operation, refractories with high resistance to erosion, abrasion, and thermal shock are essential. In the working zone, where the heated metal makes direct contact with the lining, castables or precast refractory concrete elements are used for their combination of high mechanical strength and thermal‐shock resistance. In areas subjected to less direct metal contact, one can employ refractory concretes, ramming mixes, or shaped elements, whose structures provide excellent insulation while still offering adequate mechanical durability. By implementing a multilayer lining system that includes both working and insulating layers, optimal thermal performance is achieved, directly enhancing heating efficiency and extending the service life of the pusher furnace.

Scope of offer: Lining design Refractory products supply Lining installation services

The ceramic protective layer of the pusher‐furnace walls consists of insulating ISOLUX products, chamotte SUPERTON, and high-alumina ANDALUX. Using this combination ensures stable operating conditions by minimizing heat loss and optimizing metal‐heating processes, which in turn improves technological performance and lowers operating costs through reduced energy consumption and fewer maintenance shutdowns.

The working layer of the pusher‐furnace walls must resist severe abrasion, oxidation, and thermal shock, especially where large temperature differentials occur. High-alumina andalusite bricks (ANDALUX) are most commonly used. For extensive wall surfaces, precast refractory concrete elements made from MULCAST are ideal: their uniform structure delivers excellent resistance to thermal shocks and other aggressive factors.

The arch of the pusher furnace is directly exposed to hot flue gases and extreme temperature swings during operating cycles. Under these conditions, aluminosilicate bricks with 60–80% Al₂O₃ content are required. Alternatively, for hard-to-line areas or when thicker arch linings are needed, refractory castables can be employed.

In a pusher furnace, the burners are subjected to extreme thermal and chemical stresses, requiring materials with high resistance to both temperature and aggressive substances such as metal oxides or slag. PCO Żarów supplies burner blocks made from high-alumina castables. Thanks to their strength and thermal stability, these materials effectively protect the burners from degradation, ensuring uninterrupted heating performance in the pusher furnace.

The hearth of a pusher furnace faces the most demanding conditions—intense contact with hot charge material, exposure to aggressive gases, and extreme temperatures demand a lining material with exceptional thermal and chemical resistance. PCO’s high-alumina castables offer excellent mechanical properties under heavy use, guaranteeing the hearth’s stability and long service life.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryWhich material will best protect the hearth against abrasion and clinker formation?

What multilayer lining system should be used to minimize flaking of the inner brick layer?

How should the lining be designed to achieve maximum resistance to impact and mechanical pressure during charge pushing?

Walking-beam furnace

The walking‐beam furnace is used to soak primarily large, regularly shaped steel semi‐finished products before further hot‐forming on the mill. The material is conveyed on a series of special movable beams—“walking beams”—which ensure uniform heating and thermal treatment. Continuous‐operation temperatures reach up to 1250°C. In a walking‐beam furnace, the steel passes through three main zones: preheating, transfer, and soaking. The refractory lining must be gas‐tight, resist thermal shock, and provide good insulation. This minimizes heat losses and delivers uniformly heated material, ready for subsequent processes such as rolling or forging.

Scope of offer: Lining design Refractory products supply Lining installation services

The hearth of the walking‐beam furnace is subjected to intense contact with hot charge material, aggressive gases, and extreme temperatures, requiring refractory materials with high thermal and mechanical resistance. To meet these demands, PCO Żarów recommends a high-alumina castable with improved flow characteristics, ideal for lining large surface areas. In the event of an unexpected shutdown, our “fast-dry” castables can be rapidly dried on-site, minimizing downtime and restoring furnace operation without delay.

The walking beams themselves are a critical component for heat exchange and flue‐gas transport within the furnace. PCO supplies prefabricated vertical and horizontal duct sections that can be quickly installed or replaced, greatly simplifying upgrades and maintenance. In complex junctions—such as three-way tees—our PCO WetRAM ramming mixes provide a gas-tight seal and structural stability.

The protective wall layers of the walking‐beam furnace play a vital role in thermal insulation and structural protection. A properly engineered multilayer system of aluminosilicate materials ensures stable operating conditions, reduces heat loss, and optimizes the metal-heating process.

The working layers of the walking‐beam furnace walls must be made from materials with high resistance to abrasion, oxidation, and thermal shock, especially in zones with large temperature differentials. High‐alumina andalusite bricks used in this part of the furnace ensure long‐term lining stability even under severe mechanical and thermal loads. For covering large wall surfaces, precast concrete elements are ideal: their uniform structure and ease of installation provide a coherent lining system.

The roof of the walking‐beam furnace is often exposed directly to hot flue gases and the wide temperature swings that occur during operating cycles. In this area, aluminosilicate bricks containing 60–80% Al₂O₃ are an excellent choice, as are bauxite or corundum castables. Concretes perform especially well on hard‐to‐line surfaces and when forming thicker arch linings.

Burners in the walking‐beam furnace endure extreme thermal and chemical stresses, necessitating refractory materials of exceptional resilience. PCO Żarów recommends high‐alumina corundum‐based concretes, which can be cast in place or used as prefabricated burner blocks. Their dense structure and outstanding thermal‐shock resistance guarantee long‐term stability and efficient burner performance.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryWhich ceramic material will best protect the walking beams from clinker fallout originating from heated blooms?

What lining configuration will ensure resistance to thermal stresses caused by introducing cold charge material?

Which type of material should be selected to minimize chipping of the lining at beam edges and around anchor points?

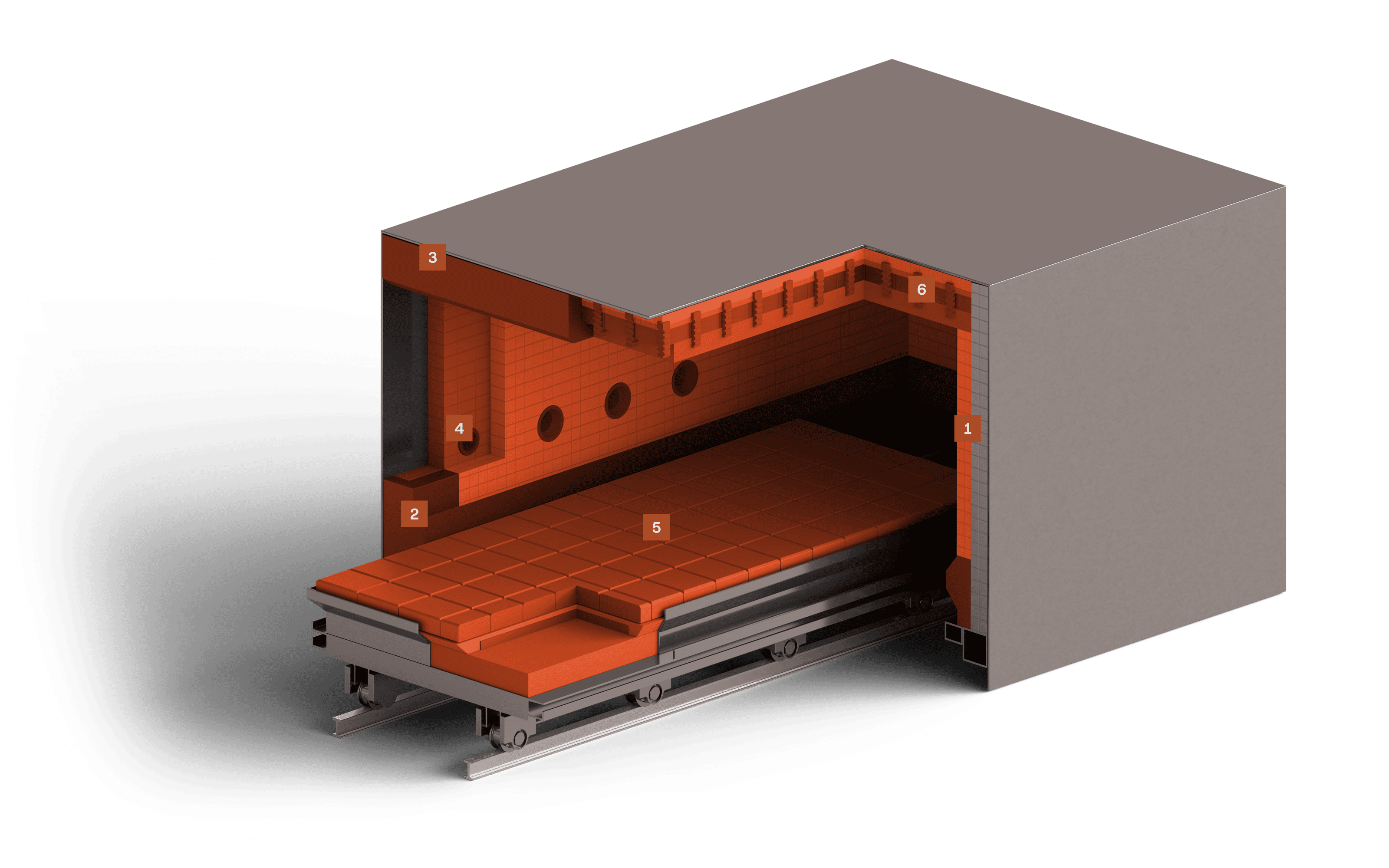

Bogie hearth furnace

A chamber furnace with a movable hearth—primarily used in forges and press shops—is designed for heat‐treating castings, stress relieving, and annealing of semi‐finished and finished products. Depending on the charge and process objectives, operating temperatures range from approximately 600 to 1350 °C. The refractory lining for a movable‐hearth furnace consists entirely of aluminosilicate bricks and modules of ceramic fiber, providing both thermal stability and resistance to the extreme service conditions encountered. PCO Żarów delivers complete lining systems for the walls and roof of the furnace, as well as a variety of hearth‐lining options—from prefabricated modules through poured castables to traditional brickwork.

Scope of offer: Lining design Refractory products supply Lining installation services

The refractory lining of the walls in a walking‐beam furnace is primarily subjected to thermal shock from the sudden temperature differences each time the hearth is withdrawn. Wall construction uses a multilayer system in which the working layer is made of insulating bricks. Because operating temperatures range only from 450 to 1250 °C, these walls serve mainly as thermal insulation and are not exposed to severe mechanical loads.

The wall skirt supports the furnace walls at hearth height. In addition to thermal shocks, this zone must resist mechanical impact from the motion of the hearth carriage, requiring materials with higher compressive strength. For this reason, dense castables or dense firebricks are most often used. Behind the working layer, insulating fiber‐module panels are installed to further enhance thermal insulation and structural stability.

The furnace door in a walking‐beam installation uses materials similar to those in the wall skirt. Here, a single dense refractory layer—without an additional insulating backing—is sufficient, and heavy refractory concrete is typically employed.

Burners in the walking‐beam furnace endure extreme thermal and chemical stresses, operating at temperatures often exceeding 1300 °C. To withstand these conditions and ensure long‐term stability, prefabricated burner blocks made from heavy, high‐alumina castables are used.

The hearth carriage is the component most exposed to thermal shock, as it cycles in and out of the furnace, cooling each time it withdraws. In many plants, this occurs several to a dozen times per hour, generating significant thermal stress. Given the large size of the charge, the lining material for the hearth must offer high mechanical strength and impact resistance. Additionally, molten spillage (“zendra”) can infiltrate expansion joints and cause refractory failure. The hearth lining consists of multiple layers, with the working layer composed of either dense castables or solid bricks.

The roof of a walking‐beam furnace is subjected to thermal shock and sustained high temperatures. Depending on furnace design, it may be lined with ceramic‐fiber modules for lighter duty or with prefabricated refractory elements installed during assembly. The roof modules combine heavy castable and insulating castable, and are secured by ceramic anchors to ensure stability.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryWhich material should be used on the furnace door and wall skirt to withstand mechanical stresses during the hearth carriage movement?

How should the hearth’s multilayer lining and ceramic expansion joints be designed to maintain integrity for as long as possible?

Which material should be selected for the furnace walls and roof to combine mechanical strength with thermal‐shock resistance during cyclic operation?

Why choose PCO?

Installation service together with refractory supply – easier project management and a single guarantor of quality

Dimensional accuracy regardless of production batch size

Support from designers and material specialists – we will help you properly select the right material and ensure supervision of the installation

Selected Products and Services for the Coke Industry

Ceramic Anchors

Precast EAF roof

ANDALUX A60Hc Unfired

Contact us

Please select the option that best describes the subject you want to discuss with us. This will help us direct your inquiry to the right person at PCO.