Energy and Waste Processing

Our offer for energy and waste processing industry

Modern energy recovery and waste processing plants operate under some of the harshest thermal and chemical conditions found in industry.

Combustion chambers, secondary burners, and flue gas systems face continuous exposure to high temperatures, alkali slags, corrosive vapors, and extreme thermal cycling. Whether in waste-to-energy (WtE) incinerators, biomass boilers, or gasification systems, refractory linings play a critical role in ensuring safety, efficiency, and equipment longevity. The most common systems include municipal waste incinerators, RDF-fired units, biomass combustion chambers, and thermal waste recovery facilities. Burning specialized waste streams like medical waste or spent batteries introduces even more complex thermal and chemical profiles. By matching refractory brick and castable composition and formats to each thermal zone, PCO works to ensure longer service life, improved thermal efficiency, and reduced unplanned shutdowns. For over a decade at PCO Group we develop specialized refractory materials, engineer solutions and provide lining installation services tailored to these demands.

What we can do for you

Design

- Preparation of furnace commissioning documentation and installation instructions for bricklayers, anchoring and expansion joint calculations, firing curve recommendations.

- Design of prefabricated ceramic components and documentation for production at the manufacturer’s facility or on-site (furnace core, flue gas pipes and ducts, rings, suspended roofs).

- Preparation of execution drawings and material lists for a complete ceramic lining project.

- Thermal flow calculations for each layer of the ceramic lining and for every zone of the boiler or furnace.

Manufacture and Supply

- Fireclay, high-alumina and insulating bricks – for every layer, from the working lining to outer insulation.

- Prefabricated concrete elements – cast and pre-fired (up to 600 °C) at the PCO plant – ready for on-site installation.

- Specialized grades of refractory materials designed for aggressive operating environments (chemical attack, thermal shocks, waste combustion products).

- Arch and wedge-shaped bricks for upper and intermediate arches, cylindrical chamber walls, and grate zone linings.

- A proven, comprehensive range of refractory concretes and gunning mixes designed for use in power boilers and biomass combustion units.

Installation services

- Long-standing experience of PCO Serwis S.A. in the installation of ceramic linings for power and heating plants.

- Inspections and condition assessments of existing linings, site survey reports, preparation of design and as-built documentation.

- Demolition and disposal of old linings, installation and pre-drying of new refractory linings.

- Production and supply of all required heat-resistant steel elements (anchors, electrodes, consoles, brackets).

- Technical consulting, warranty and post-warranty service.

Furnaces and high-temperature industrial equipment

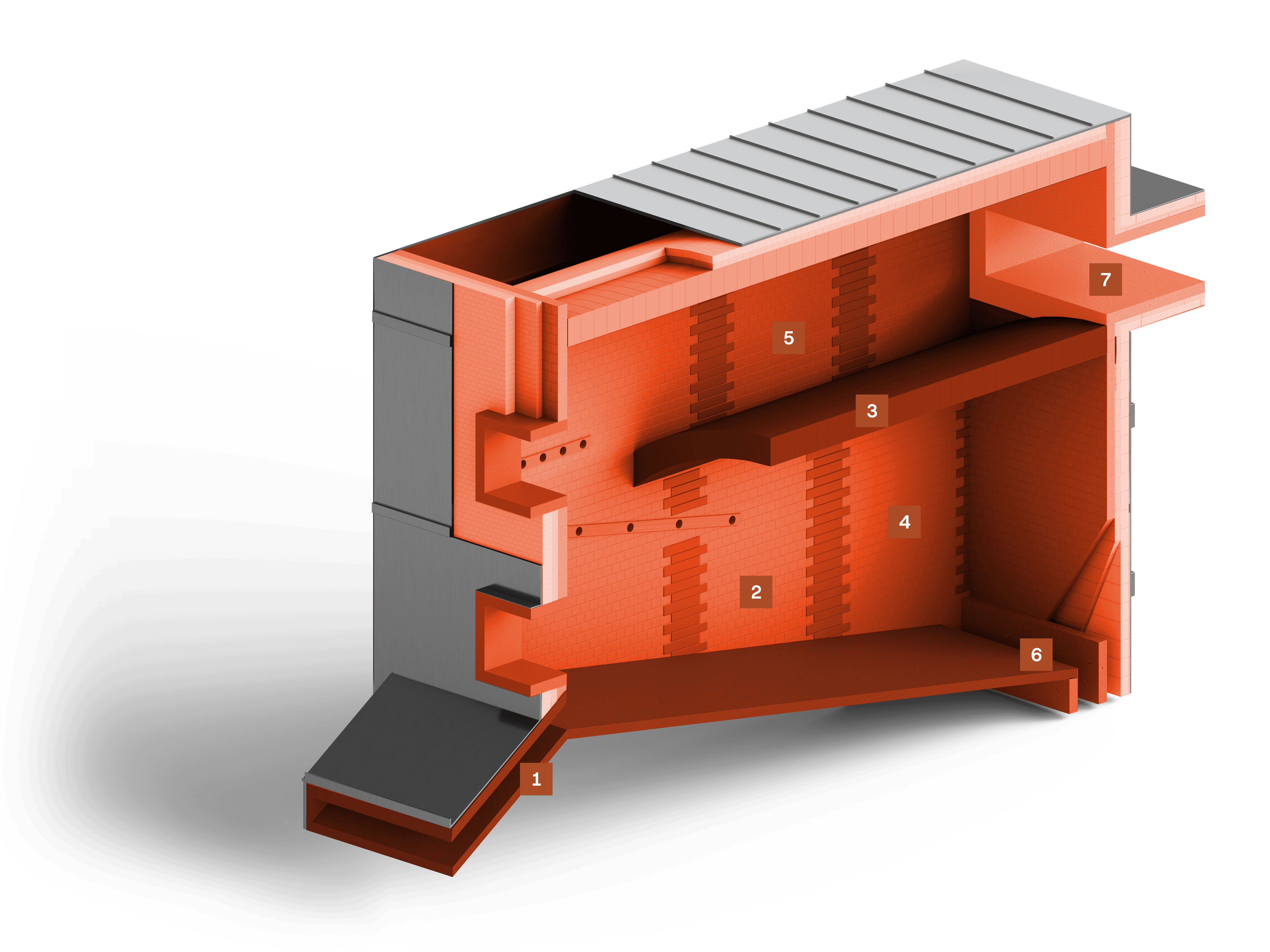

Biomass Boiler

In biomass boilers, refractory ceramic linings play a key role in protecting structural components from the effects of high temperatures and aggressive biomass combustion products. During operation, the temperature inside the boiler often fluctuates between 800–1200 °C, requiring the use of refractory materials with excellent thermal resistance. The lining must also prevent the accumulation of ash and aggressive chemical compounds, which may lead to corrosion or surface erosion. The design of ceramic linings in biomass boilers focuses on selecting materials that offer high thermal shock resistance and can withstand the fluctuating chemical composition of flue gases. This ensures long-lasting performance with minimal degradation risk. To ensure the proper residence time of flue gases in high-temperature zones, biomass boilers are typically divided into: a combustion zone – characterized by intense combustion processes and high temperatures, with distinct operational areas using various lining technologies (prefabricated shapes, castables, fired bricks), and a heat recovery zone – where the refractory lining mass is relatively low, and the main goal is fast heat absorption and effective cooling of flue gases.

Scope of offer: Lining design Refractory products supply Lining installation services

This is where biomass enters the combustion chamber. The main risk factors are thermal effects (up to 750 °C), high humidity, initial gasification, reducing atmosphere, and moderately low temperature. Suitable linings include bricks, prefabricated elements or castables. Typically, a two- or three-layer system is applied: working layer plus one or two insulating layers. Commonly used are high-duty fireclay bricks (45%+ Al₂O₃), with high strength and low iron oxide content.

This zone extends along the boiler grate and is exposed to very high temperatures, thermal shocks, and steep temperature gradients (200 to 1200 °C). Mechanical wear from fuel movement on the grate is also a risk. Two-layer systems are typical; recommended solutions include reinforced prefabricated concrete shapes and insulating protective layers.

This roof separates the combustion zone from the burnout zone. It ensures complete combustion of biomass in the lower zone and directs flue gases to the boiler outlet. It also separates temperature zones: ~850 °C below, >1200 °C above. The combustion side is more aggressive than the burnout side. Due to the temperature difference, andalusite-based products are recommended for their thermal shock and abrasion resistance.

This zone features high temperatures exceeding ash softening points. The oxidizing atmosphere supports complete combustion, and secondary air nozzles may be used to intensify gas mixing. Temperatures range from ~900 °C above the grate to ~1100 °C after the nozzles; drier biomass may cause spikes up to 1400 °C. Linings are made of fired bricks or castables and must resist high temperatures, oxidizing environments, and air nozzle impacts.

This zone, often accompanied by an intermediate roof, finalizes the combustion process at high temperatures in an oxidizing atmosphere. Intense chemical reactions occur here. Solutions are similar to the combustion zone, using fired bricks or castables. Shape and thickness must match 950–1200 °C to ensure process continuity.

Lower temperatures (650–850 °C), but increased friction due to material movement. Post-carbonate burnout may also occur, affecting lining behavior. While thermal demands are lower, abrasion resistance is key. Materials should offer high wear and friction resistance and maintain chemical stability at lower temperatures.

This section transfers heat from the chamber to the waste heat boiler. The outlet and inlet should match geometrically to maintain flow and minimize pressure drops. Castable linings are preferred for ease of application. Adiabatic chamber temperatures can reach 1200 °C. High-alumina castables (sprayed or prefabricated) are suitable.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquirySelecting refractory materials and layering (working + insulating) that balance heat protection in the combustion/after-burning zone (up to 1 200–1 400 °C) with efficient heat transfer and low shell temperature.

Designing the intermediate roof to resist high thermal gradients (≈ 850 °C below vs > 1 200 °C above) and strong gas turbulence without cracking or spalling.

Preventing alkali and chloride corrosion as well as ash build-up near the grate to extend lining campaign life.

Grate-Fired Boilers

In grate-fired boilers, where combustion occurs directly on the grate, refractory ceramic linings are subjected to extremely variable working conditions, combining high temperatures (typically between 1000–1300 °C) with intense mechanical and chemical stress. The linings in these units must withstand constant exposure to the combustion bed, ash, and other combustion products. This demands high resistance to both abrasion and chemical corrosion. Additionally, rapid temperature fluctuations and direct contact with the grate require the use of specialized ceramic formulations that offer flexibility and the ability to absorb thermal stress. A key factor is the precise selection of refractory material that will maintain the integrity of the lining under harsh conditions while ensuring energy efficiency and combustion process stability.

Scope of offer: Lining design Refractory products supply Lining installation services

The ignition roof is a critical element influencing boiler performance. It absorbs heat from the flame and transfers it to the grate below to dry and ignite the fuel. The roof material is exposed to gasification products and reducing atmosphere, as well as rapid temperature increases during startup (up to 1100 °C). It can be made from suspended shapes, poured into formwork, or assembled from prefabricated segments. Poor performance leads operators to maintain the flame directly beneath it, which negatively affects material lifespan, flue gas quality, and overall boiler efficiency

Screen tube deviation boxes (manholes, viewports, pressure and temperature sensors, etc.) require refractory sealing. These areas are typically lined with castables rated at ≥1350 °C.

Boiler walls (on dense linings) are exposed to different conditions depending on placement. In the combustion chamber, temperatures can reach 1100 °C—higher than in the second pass. The purpose of the walls is to contain flue gases and prevent external air from entering (as boilers operate under negative pressure), which would lower efficiency. Walls are exposed to flue gases, flame radiation, and slag buildup (if combustion is suboptimal).

This area is subject to frequent temperature changes and mechanical abrasion due to fuel flow. Solutions are primarily based on fired bricks and occasionally on prefabricated concrete elements. The design must address thermal fluctuations and abrasion, often requiring multilayer lining systems. High mechanical strength and thermal shock resistance are crucial. In case of local blow-through, process temperature may spike up to 1600 °C.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryEnsuring abrasion resistance in the grate and rear-wall zones exposed to solid fuel and ash at fluctuating temperatures.

Protecting the lining against sudden temperature spikes up to 1 600 °C and minimizing thermal-shock-induced cracking.

Choosing between fired bricks, castables or precast shapes — and arranging a multilayer system that maintains process stability.

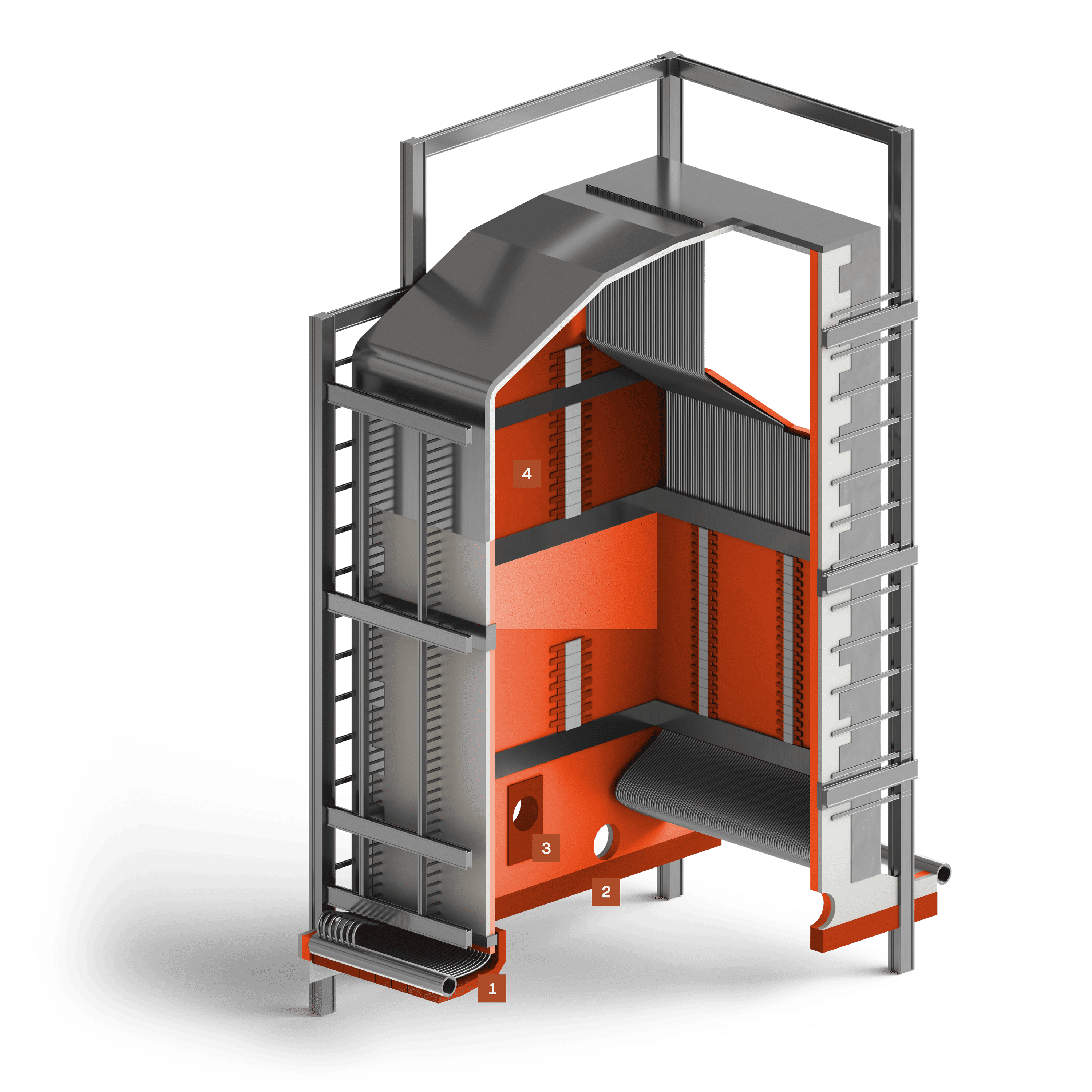

Fluidized Bed Boilers

In fluidized bed boilers, refractory ceramic linings must withstand very specific conditions caused by the fluid-like behavior of fuel and ash. This results in constant mechanical and chemical stresses due to dynamic interactions. Operating temperatures typically range from 850–1100 °C. The linings are subject to continuous abrasion, chemical erosion, and the impact of suspended particles in the gas stream. Therefore, specialized ceramic mixes are required to provide high abrasion resistance while effectively dissipating heat and reducing thermal stress. Optimizing ceramic lining design in fluidized bed boilers focuses on ensuring uniform heat distribution and minimizing localized overloads—both critical to maintaining operational stability and combustion efficiency.

Scope of offer: Lining design Refractory products supply Lining installation services

The nozzle bottom is where air, heated to about 220 °C, is injected through multiple nozzles to fluidize the bed. The space between the nozzles is filled with refractory castable. Since the nozzles direct air downward, erosion occurs. A step at the wall transition is also common. Temperatures in this area are relatively low (~600 °C).

These walls are in direct contact with the fluidized bed and include igniter burners, fuel and sorbent inlets, return material inlets from separators, manholes, etc. The main function of the lining here is to protect the pressure parts from bed abrasion. Temperatures do not exceed 900 °C. In discontinuities of the screen, the lining can be thick, while on-screen areas it is usually 50–80 mm above the tube peaks. A dense network of cracks may form here—proper anchor density is essential to maintain durability.

These ducts, connecting separators (in CFB boilers) or the combustion chamber (in BFB boilers) with the convective part of the boiler, transport relatively clean and low-eroding flue gases at 850–950 °C.

These ducts connect the combustion chamber to the separators (in CFB boilers). They carry highly erosive flue gases at 850–950 °C. Due to cross-section changes that accelerate gas flow, erosion intensifies. These ducts can be either screened or insulated. In screened ducts, the roof is usually gunned, the floor cast, and the walls may be gunned, cast, or made from prefabricated elements. Lining is typically thin. For thin linings, self-flowing castables like PCOCAST BNAB Fl or MULCAST BN80M Fl are used. In thicker sections (e.g., compensators), vibrated castables such as PCOCAST BMAB160 or PCOCAST BN160AZS (for harsh conditions) are recommended.

Hot gas cyclones (used in CFB boilers) direct pre-cleaned flue gases into the convective section of the boiler. The atmosphere is strongly reducing, with temperatures ranging from 850–950 °C. In screened cyclones, the roof is typically gunned, and the walls are either cast, rammed with plastic mixes, or made of prefabs with thin linings. In insulated cyclones, the roof is also gunned, while walls can be brick-lined with wedges, cast, or prefabricated. The working layer is thicker, and insulation must effectively block heat loss and reduce casing temperature.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquirySelecting castables with high wear resistance to particle erosion in the bed (850–1 100 °C) while limiting thermal-stress cracking.

Designing hot cyclones and separators (reducing atmosphere 850–950 °C) with optimal wall thickness and insulation to reduce erosion and shell overheating.

Maintaining flue-gas ducts (screened vs insulated) to minimize heat loss and gas corrosion while extending the life of gunned or cast linings.

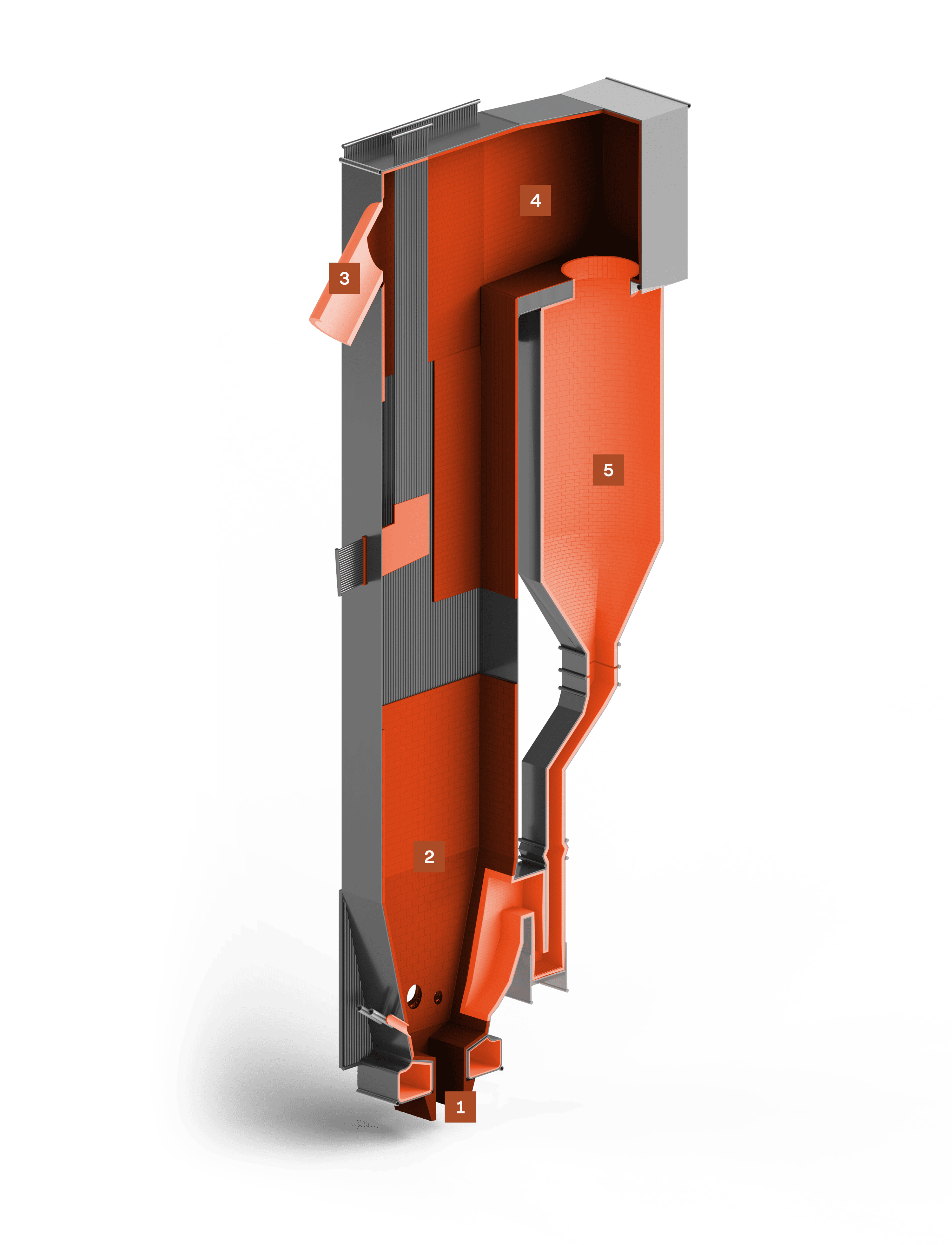

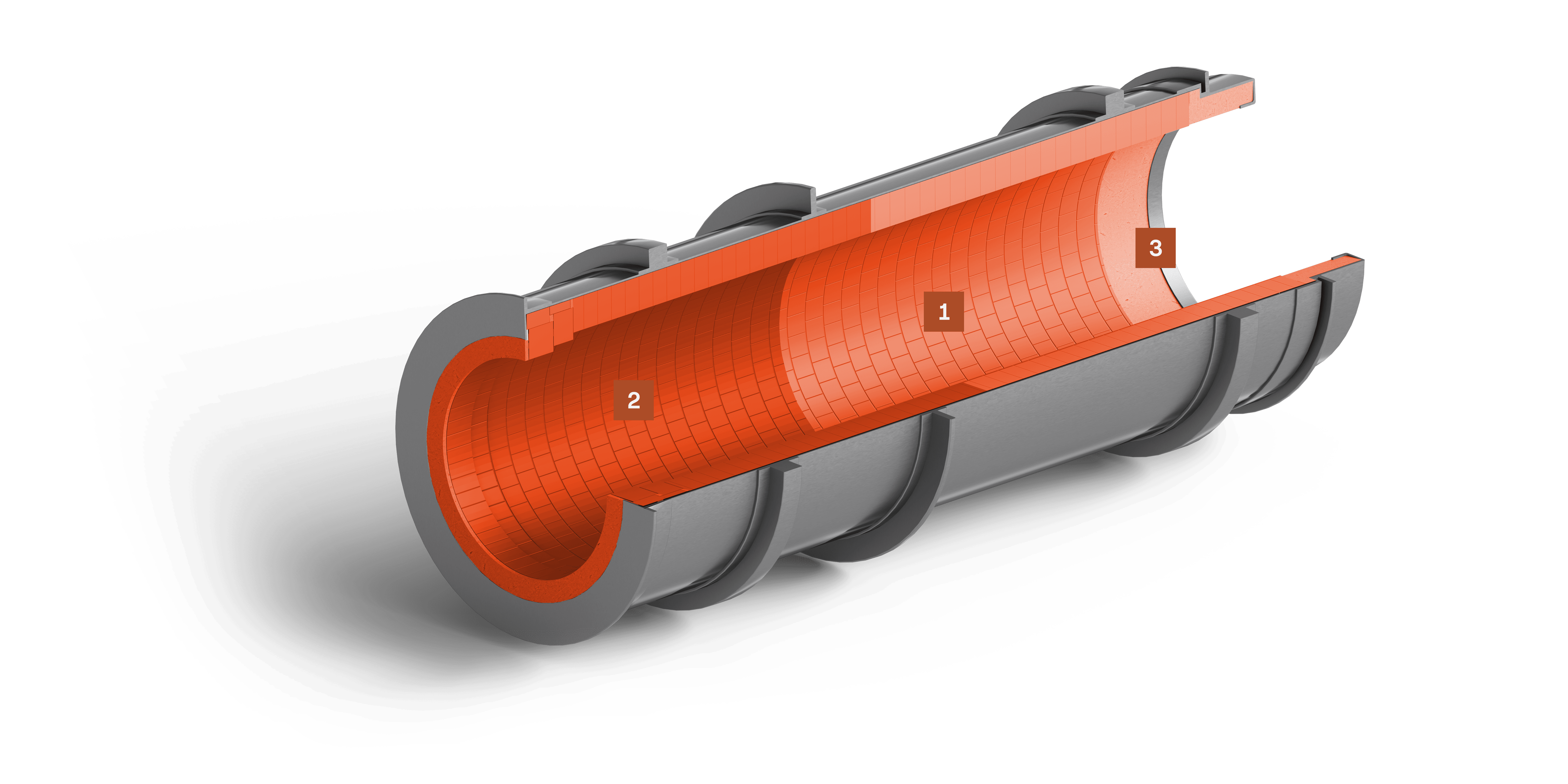

Rotary Kilns for Waste Processing

Rotary kilns for waste processing operate in extremely complex environments. Refractory ceramic linings must endure not only high temperatures (often ranging from 1200–1450 °C) but also the aggressive chemical nature of waste materials and their combustion by-products. These linings are exposed to variable and often sudden thermal cycles, as well as corrosive substances, requiring ceramic materials with enhanced resistance to thermal shock, chemical erosion, and abrasion. A key design challenge in rotary kilns is ensuring uniform heat distribution across the lining while minimizing the impact of aggressive process conditions.

Scope of offer: Lining design Refractory products supply Lining installation services

This is the core area where gasification and partial combustion of waste occur. Due to rotation, the lining is cyclically heated (when on top) and transfers heat to the waste (as it rolls over it). Lining requirements are determined by process parameters such as environmental aggressiveness and temperature. Most commonly, a single-layer lining is used, made of high-alumina wedge bricks—typically andalusite or corundum-based. Areas around manholes or burner ports are lined with refractory castables rated above 1600 °C.

These sections accumulate carbonate and ash to complete gasification or combustion before the materials leave the kiln. Refractory lining consists of high-alumina fired bricks in the working layer (andalusite or corundum products) and fireclay/insulating products in the protective layers.

The front section delivers the feed/waste to the installation. Depending on the process (co-current or counter-current), it may include a burner and air nozzles. The front plate operates under highly variable thermal conditions and is exposed to strong temperature gradients, as well as evaporated and gasified waste products. It is made from monolithic high-alumina castable or prefabricated concrete elements.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryAchieving uniform heat distribution and resistance to chemical attack under variable gas composition and 1 200–1 450 °C operation.

Choosing materials for shell sections and constrictions (andalusite / corundum + protective layers) to reduce wear and maintain cylindrical geometry.

Protecting burner and access-door zones locally exposed to > 1 600 °C.

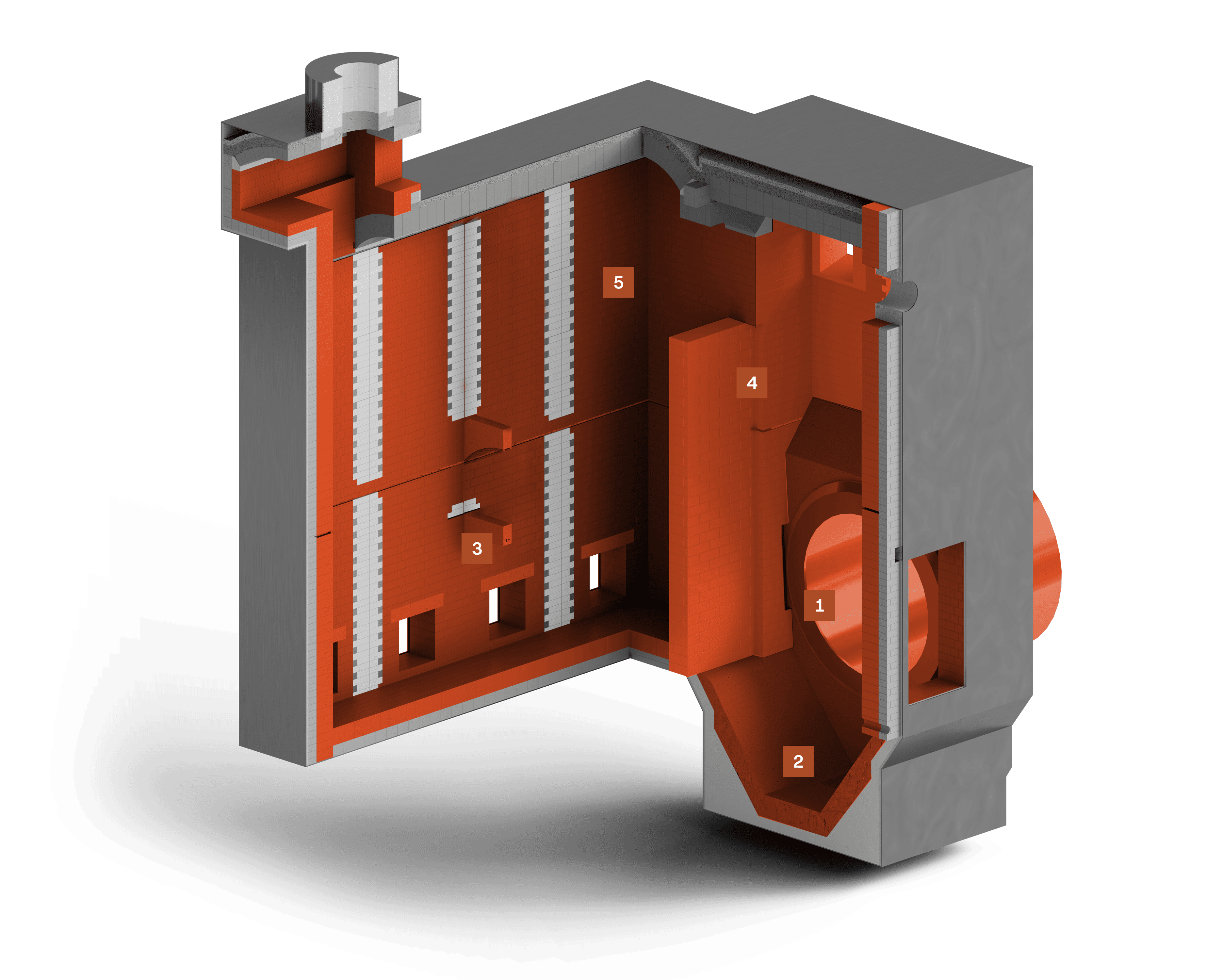

Afterburning Chamber

The afterburning chamber is a unit that enables the continuation of the combustion process following the rotary kiln stage – specifically, the burnout of gasification products and carbonates. Combustion inside a rotary kiln occurs in an oxygen-deficient atmosphere. In contrast, the afterburning chamber introduces additional air, shifting the process environment to an oxidizing one. This change requires a different type of refractory lining, as the two atmospheres affect ceramic linings in very different ways. Depending on the zone, the afterburning chamber is subject to mechanical erosion (from falling material), chemical attack (from process gases), and thermal shocks (from injected air). Throughout the entire chamber, the refractory lining is made from high-alumina materials.

Scope of offer: Lining design Refractory products supply Lining installation services

This is a critical transition zone where gases are directed to subsequent stages of the process, while heavier fractions – such as slag, ash, and unburnt residues – fall downward. Operating conditions here are defined by moderate temperatures (typically not exceeding 950 °C) and a slightly oxidizing atmosphere. The zone experiences intense mechanical erosion caused by material movement and impact from heavy particles dropping from the kiln. For biomass-fired units, MULCAST BN50M is recommended. For municipal or medical waste incineration, MULCAST BN80MZr is preferred.

This zone completes the burnout of carbonates—carbon-rich residues from the gasification and combustion of fuel in the rotary kiln. Temperatures do not exceed 950 °C. Though subject to significant mechanical wear from contact with solids and dynamic airflow, the chemical environment is less aggressive, as most reactive compounds are carried away in earlier process stages. Commonly used materials include MULCAST BN50MZr and PCOCAST BNAK160, which are recommended for applications requiring high abrasion resistance and dimensional stability.

In this section, the oxidation process intensifies. Temperatures are generally kept below 1000 °C to prevent lining buildup due to local oxygen deficiency. Here, flue gas compounds mix with tertiary air, causing rapid temperature increases. Refractory linings should consist of ABRAL brick products enriched with silicon carbide or special castables such as BNSiC, which offer excellent chemical and thermal resistance and perform reliably under high-temperature oxidizing conditions.

This zone finalizes the oxidation of flue gases formed during waste combustion. Its main function is to ensure sufficient residence time at high temperature and complete mixing with secondary or tertiary air to eliminate any remaining combustibles. Temperatures can exceed 1050 °C. Similar to the combustion zone, ABRAL bricks and BNSiC castables are recommended.

Mixing baffles plays a critical role in the final phase of combustion. Their function is to prolong flue gas residence time under oxidizing conditions and to intensify mixing with secondary or tertiary air. Temperatures in this section may also exceed 1050 °C. Auxiliary gas burners are often activated to maintain the required thermal profile. Due to the process conditions and oxidizing environment, high-SiC refractory bricks are used in baffles to ensure durability and resistance to both heat and corrosion.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryAdapting refractory composition from reducing to oxidizing atmosphere to avoid accelerated wear during process changes.

Reinforcing the inlet area from the rotary kiln (≤ 950 °C, strong mechanical erosion) to preserve flow cross-section and shape.

Applying SiC-containing products in the flame and mixing zones (> 1 050 °C) to extend residence time and chemical resistance.

Why choose PCO?

All bricks, mortars, and castables from a single manufacturer

Product Portfolio Developed in Collaboration with Industry Practitioners

We have our own team of engineers and designers

Selected Products and Services for the Coke Industry

PERLITEX LPN™

On-site presence and technical guidance from PCO during lining repair works

Removal and disposal of spent ceramic linings from incinerators – regardless of fuel type

Contact us

Please select the option that best describes the subject you want to discuss with us. This will help us direct your inquiry to the right person at PCO.