PCO Group

Synergy effect

Polska Ceramika Ogniotrwała “Żarów” sp. z o.o. is an integral part of the refractory ceramics segment of the LODE Group.

This segment consists of three key units: the producer of refractory raw materials JARO S.A., the producer of refractory materials PCO “Żarów”, and the service and installation company PCO Serwis S.A.

These three entities cover successive stages of the supply chain - the production of raw materials, refractory materials, and the provision of service and installation services.

PCO Group

JARO S.A.

JARO is the only producer of chamotte refractory aggregates in Poland. The company extracts from its own clay deposits, particularly refractory, ceramic, and sealing clays, and processes mineral raw materials. The company's products are mainly used in the production of refractory and sanitary ceramics, as well as in metallurgy, foundry, and construction industries.

PCO Żarów

The company manufactures aluminosilicate refractory materials such as shaped bricks, concrete, mortars, and concrete prefabricates. The products are designed for industrial applications at temperatures up to 1700°C. The headquarters and manufacturing plant are located in Żarów. PCO employs over 250 specialists and provides refractory solutions to customers worldwide.

PCO Serwis S.A.

PCO Serwis is now comprised of over 130 specialists providing services in the repair, modernization, and installation of production and technological lines, including ceramic linings, steel structures, transport equipment (conveyors, pneumatic transport), grinding equipment, dust collectors, separators, screens, and crushers.

Main benefits of synergy

In creating a capital group, we aimed to maximize the benefits our clients can achieve through this integrated approach.

Comprehensive Service

We provide support from the technical design stage, through product manufacturing, to the installation of refractory linings. Choosing a company that offers both refractory materials and their installation service ensures comprehensive customer service, simplifying the process and saving time. Quality assurance is higher as one company is responsible for the entire process, minimizing the risk of problems. Consolidated technical support facilitates quick problem resolution, and cost and schedule optimization brings additional savings. Reduced risk of logistical and communication errors increases project deadline reliability.

Cost-Effective Solutions

The ability to combine knowledge in raw material production, refractory material manufacturing, and installation technology gives us significant opportunities for cost optimization in investments. Our cost analysis does not limit itself to the purchase cost of refractory ceramics but covers a much broader scope, including installation cost and time. This helps our clients choose the best solution for their specific situation.

Continuous Service Availability

Thanks to the synergy and mutual dependence of the companies within the group, clients can expect continuous service availability, contributing to operational stability.

Innovations and Product Development

Our clients benefit from innovations and the development of new products or services within the capital group. When designing our refractory solutions, we utilize knowledge and experience from both raw material production and refractory lining installation. This continuous improvement allows us to create products that last longer, are easier to install, and provide cost-effective complete solutions.

Protection Against Market Uncertainties

The capital group enables us to better manage various types of risks, helping to minimize potential problems and uncertainties. Our own resources of key raw materials, such as clays and refractory aggregates, ensure long-term business stability. By choosing our solutions, clients can be confident that once-tested materials will be available in the same quality in the future.

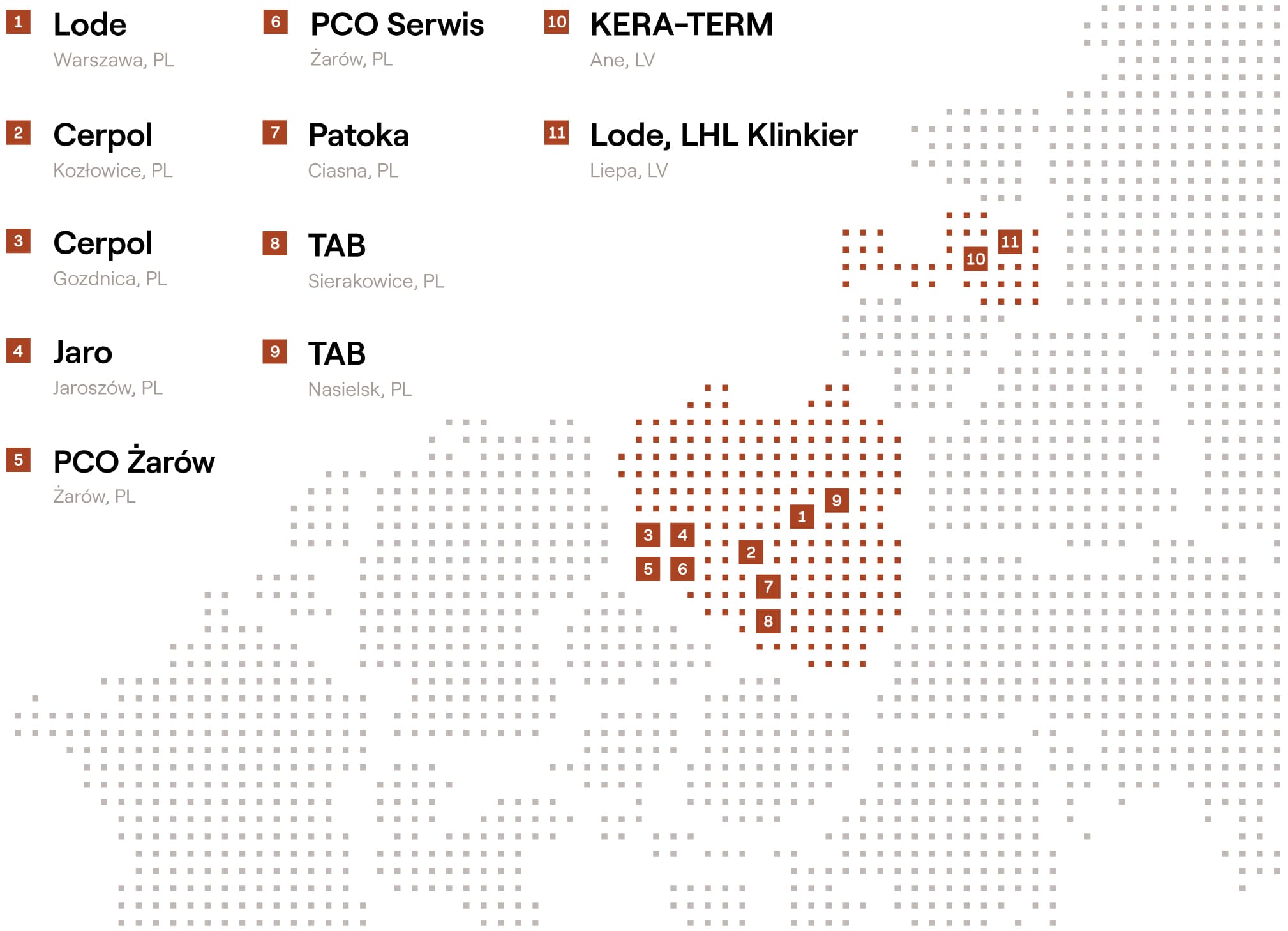

LODE Group

Since 2018 PCO is part of the LODE Group. LODE is the largest producer of building materials in Central and Eastern Europe, employing over 900 people across 9 production plants in Poland and Latvia.

LODE Group specializes in ceramics and products such as ceramic blocks, clinker bricks and pavers, as well as concrete prefabricates and blocks. The well-known product brands include: LODE, Keraterm, LHL Klinkier, Patoka, Cerpol, and TAB.

The experience, knowledge, and resources provided by PCO's membership in the LODE family support the improvement of our refractory solutions. The intensive development of the plants and the expansion of the group's refractory division through acquisitions mean that every year PCO's offering is expanded with additional elements that increase benefits for our clients.

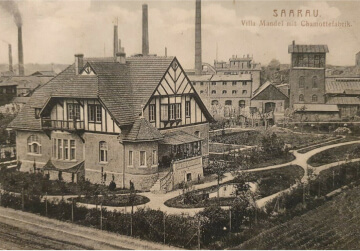

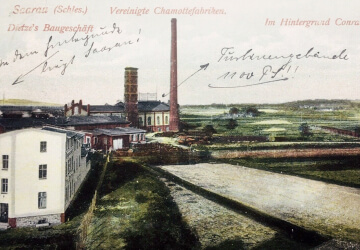

Our history

Contact us

Please select the option that best describes the subject you want to discuss with us. This will help us direct your inquiry to the right person at PCO.