Primary Aluminium Production

Our offering for the primary aluminium production process

In recent years, primary aluminium smelters worldwide have been facing significant operational challenges that directly affect the profitability of aluminium production.

One of the key risk factors is the cost of electrical energy, accompanied by increasingly strict environmental regulations, particularly in the production of carbon anodes. Primary aluminium production consists of processes carried out under severe operating conditions for refractory ceramics, including high thermal and chemical loads. Our experience in the aluminium industry covers the supply of complete lining systems for newly built production lines as well as the regular delivery of refractory materials for maintenance and repair works.Our product portfolio includes refractory grades suitable for installation in furnaces and electrolytic cells of all leading technologies and engineering companies, such as AP Technology / Pechiney, Riedhammer, Fives, CFT and SAMI.

What we can do for you

We design

- Large-format bottom lining blocks for aluminium electrolytic cells (BRO bricks)

- Dedicated shapes for flow channel walls and prefabricated top blocks for cell closure systems

- Preparation of detailed shop drawings and bill of materials calculations for ceramic lining designs of electrolytic cells, transport ladles and chamber furnaces

- Thermal flow calculations for each zone and layer of the refractory lining

We manufacture and supply

- Refractory bricks and castables based on various refractory raw materials – suitable for every lining layer, from the working lining to external insulating layers

- Precast refractory elements, cast and pre-fired (up to 600 °C) at the PCO plant – ready for on-site installation

- MORTALEX refractory mortars with alumina content ranging from 42% to 60% Al₂O₃ for anode furnace brickwork

- BAUXITEX bauxite bricks with 80–85% Al₂O₃ and low porosity for aluminium transport ladles

- NORMATON AX28 – cryolite-resistant BRO-grade bricks for the working lining of aluminium electrolytic cells

We install

- Installation of brickwork linings for open and closed anode furnaces by PCO Serwis S.A.

- Inspections and technical assessments of refractory linings, including site reports and preparation of design and as-built documentation

- Manufacturing and supply of all required heat-resistant steel components (anchors, electrodes, brackets, supports)

- Technical consultancy as well as warranty and post-warranty service

Furnaces and high-temperature industrial equipment

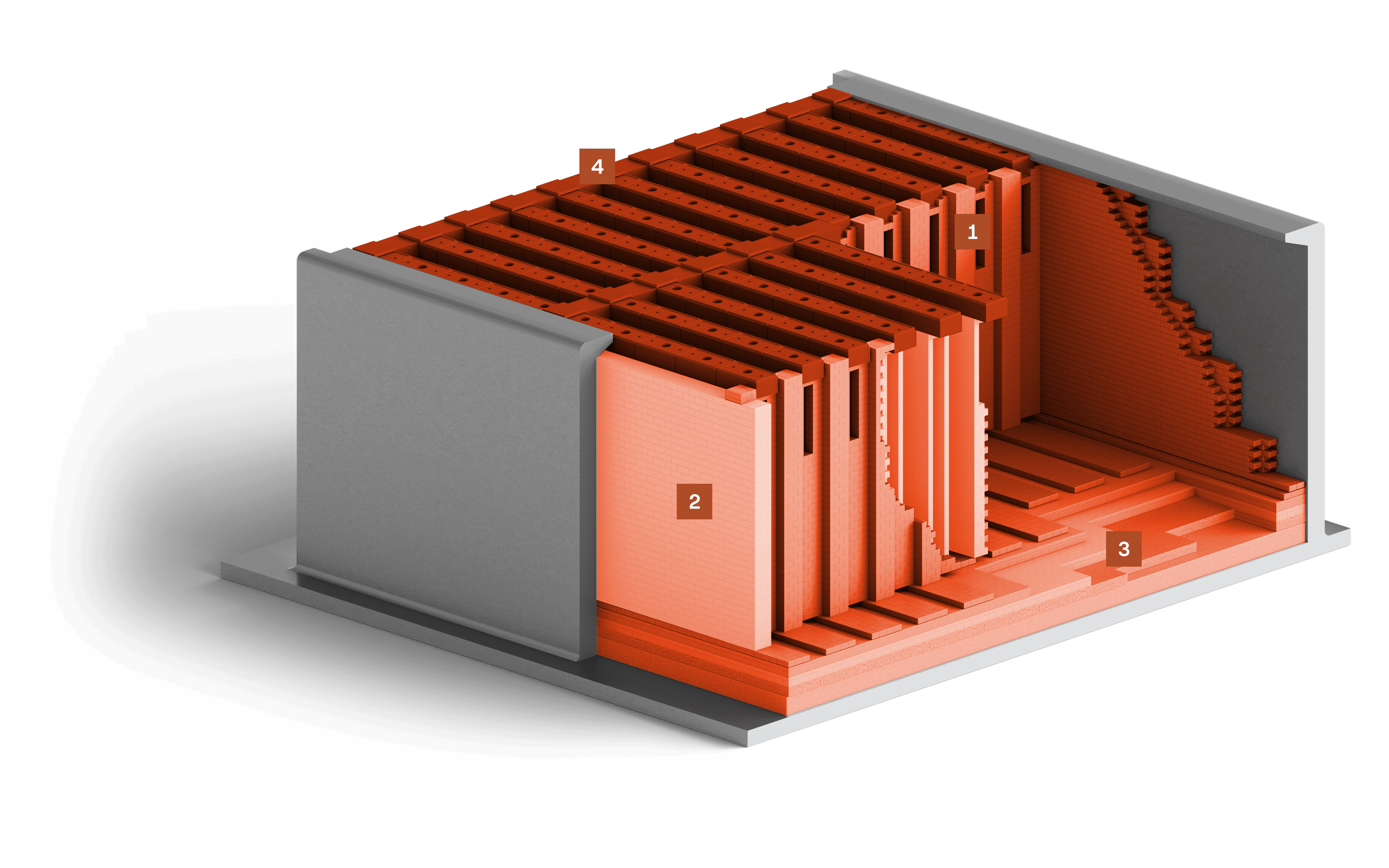

Open Anode Furnace – overview of solutions

The open anode furnace is used for the baking of carbon blocks (carbon anodes) applied in electrolytic cells for primary aluminium production. The calcination process of carbon blocks is carried out in chambers heated indirectly via flue channels. Due to the operating mode of the furnace and its open design, local temperature gradients frequently occur, increasing the risk of lining deformation. The highest thermal loads are observed in the walls of the fire channels, through which hot exhaust gases are conveyed. The most critical challenges for refractory components are related to deformation caused by chemical corrosion and material creep under high temperature and the penetration of sodium vapours originating from the anode material. The furnace lining must ensure dimensional stability, resistance to cyclic temperature changes and limited permeability to corrosive gases.

Scope of offer: Lining design Refractory products supply Lining installation services

The end walls of the furnace are exposed to high temperatures, particularly during heat transfer from the fire channels and throughout the baking cycle. This zone is characterised by severe thermal stresses and a high risk of cracking resulting from temperature differences between the furnace interior and the surrounding environment. Materials used in this area should provide structural stability, high resistance to thermal shock and limited capacity for the accumulation of sodium and fluorine compounds.

Fire channels represent the most thermally loaded part of the furnace. Inside these channels, hot gases and flames flow, transferring heat to the baking chambers. Strong infiltration of reactive gases originating from the anode material occurs, leading to the formation of a glassy degradation phase. The refractory lining must ensure low porosity, resistance to the penetration of sodium vapours and fluorides, as well as long-term dimensional stability under high temperatures and fluctuating thermal loads.

The furnace floor is responsible for carrying the load of the charge and the filling material. This area is exposed to long-term thermal impact, contact with volatile organic and inorganic compounds, and the possible accumulation of condensates and contaminants. Materials used in this zone should be characterised by high creep resistance and good thermal insulation properties.

The upper lining layer provides thermal protection of the baking zone and minimises energy losses. It also plays a functional role in the furnace firing system. Due to the presence of burners, local overheating and thermal shocks may occur in this area. Materials applied in this zone should feature low thermal expansion, resistance to heating and cooling cycles, and low thermal conductivity.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryChemical corrosion of flue walls caused by sodium and fluorine vapours from the anode material, leading to the formation of a glassy degradation phase and deformation of the fire channels.

Local temperature gradients resulting from the open furnace design, causing uneven thermal stresses and cracking of the lining in the head walls and bottom areas.

High-temperature creep of the fire channel wall materials — gradual loss of lining geometry restricts flue gas flow efficiency and reduces the uniformity of anode baking.

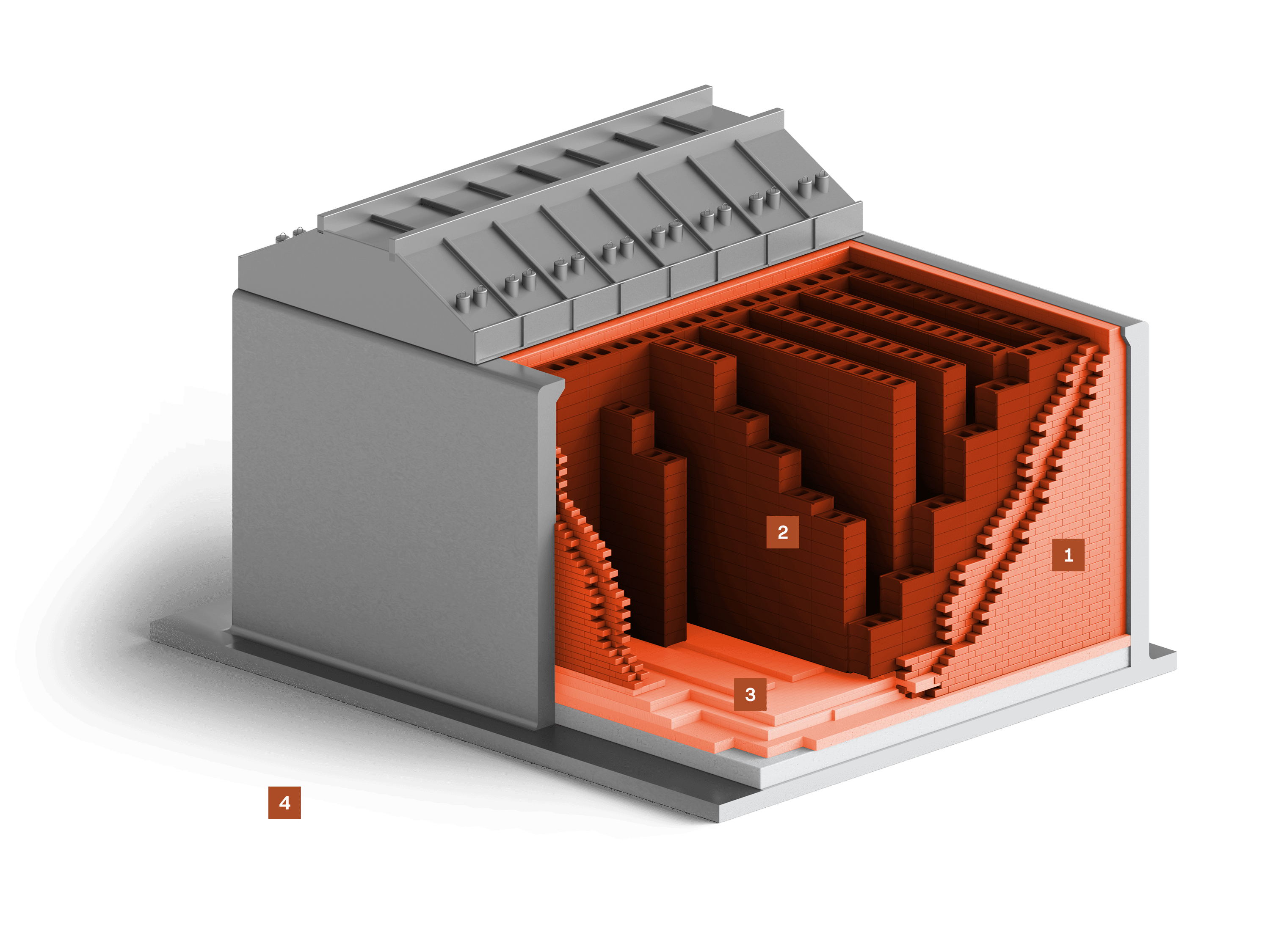

Closed Ring Furnace – overview of solutions

The ring furnace is an installation used for the baking of carbon electrodes applied in high-temperature metallurgical processes, such as the production of carbon cathodes and anodes for the aluminium industry. The process carried out in a ring furnace is, in principle, similar to that of open furnaces; however, the key difference lies in the firing system applied in each design. In the furnace chambers, carbon blocks are placed, while the spaces between the blocks and the chamber walls are filled with a protective carbon packing material. The thermal treatment of the carbon blocks is achieved through indirect heat transfer from exhaust gases flowing through vertical heating flues into the chambers. The furnace structure includes, among others, head walls, heating flue walls, the furnace floor and top blocks. Due to the cyclic operating mode and high temperatures (reaching up to approximately 1350 °C), the installation requires carefully selected refractory materials with high chemical resistance, good shape stability and low porosity.

Scope of offer: Lining design Refractory products supply Lining installation services

Head walls are located at the ends of the baking chambers and act as structural elements closing the system. They are exposed to high temperatures, fluctuating thermal loads and mechanical stresses resulting from the thermal expansion of the entire structure. Materials applied in this zone must provide resistance to thermal shock, dimensional stability and durability under long-term high-temperature operation.

Heating flues are a key element responsible for heat transfer to the charge. Materials in this zone must exhibit good resistance to high-temperature creep and deformation, as well as high resistance to temperature fluctuations.

The furnace floor is subjected to high mechanical loads from the charge as well as the process temperature. In addition, mineral compounds and contaminants from the packing material may accumulate in this area. The refractory lining in this zone should provide high compressive strength, abrasion resistance and low water absorption, preventing long-term degradation.

Waste gas channels are responsible for the discharge of gases generated during the baking of carbon blocks. Due to contact with a mixture of exhaust gases, corrosion, condensation of aggressive components and volumetric changes of the refractory material may occur. Materials applied in this zone must exhibit resistance to aggressive process gases, chemical stability and tightness, limiting the penetration of contaminants into the furnace structure.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryCreep and deformation of heating channel walls at temperatures up to 1350 °C under cyclic furnace operation, leading to channel narrowing and reduced heating efficiency.

Condensation of aggressive flue gas components in the exhaust channels, causing chemical corrosion and loss of structural tightness of the furnace.

Mechanical stresses in the head walls caused by thermal expansion of the entire system — repeated heating and cooling cycles lead to cracking and loss of chamber sealing.

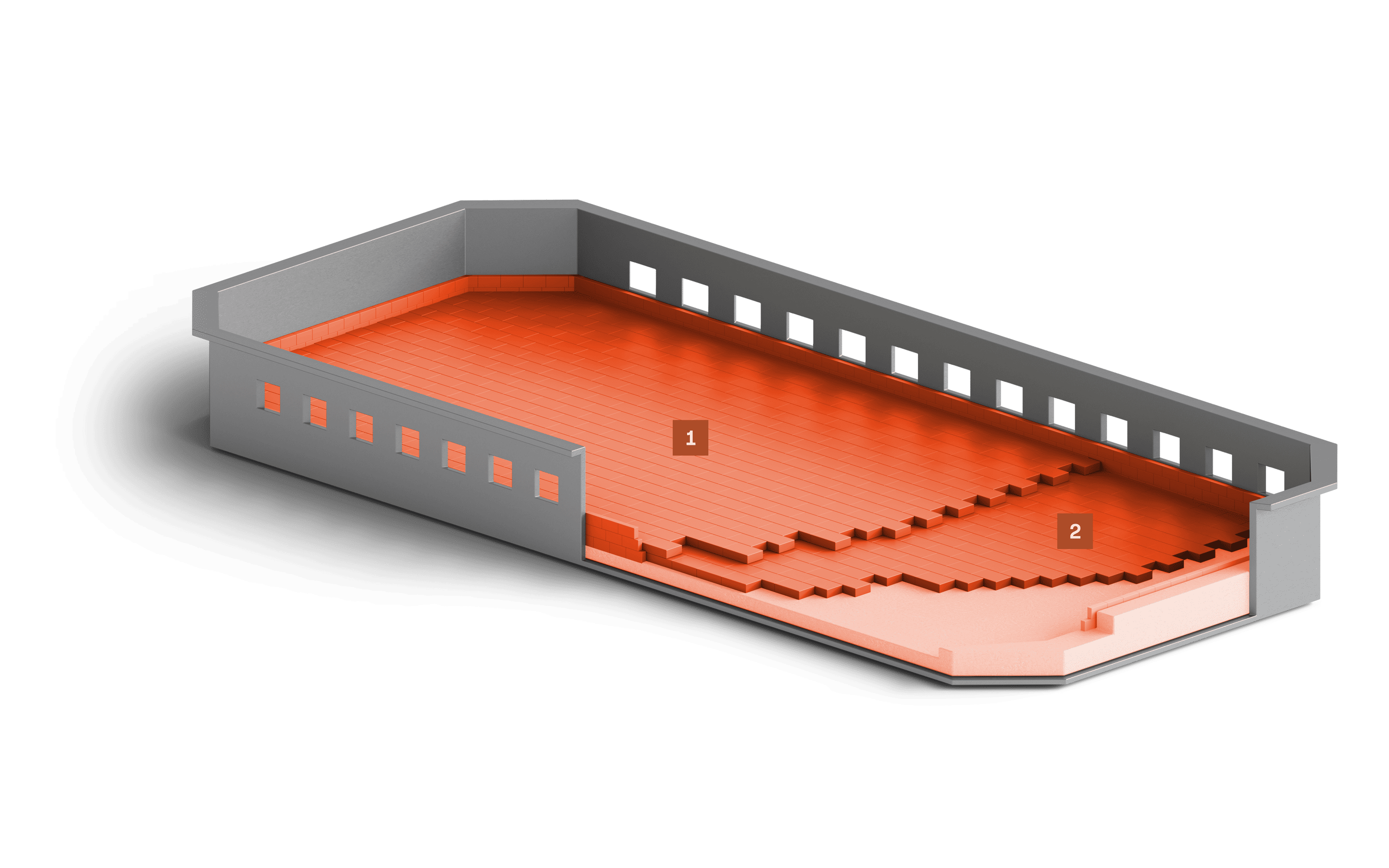

Electrolytic Cell – overview of solutions

Electrolytic cells are key installations used in the production of aluminium by the electrolysis of alumina. Inside the cell, alumina is decomposed electrolytically, resulting in the formation of molten aluminium, which accumulates at the bottom of the cell. The construction of an electrolytic cell is based on a system of carbon cathodes installed in the bottom of the shell and surrounded by a multi-layer refractory and insulation lining. This lining must ensure appropriate thermal conditions, tightness and chemical resistance throughout the entire service life of the cell. Due to the direct contact with the electrolyte bath and the influence of electric current, each lining component must meet strict technical requirements, including resistance to corrosion, penetration of salts, and thermal stresses.

Scope of offer: Lining design Refractory products supply Lining installation services

The barrier layer is located beneath the carbon electrodes (cathodes), and its primary function is to prevent the penetration of the electrolyte bath into the underlying insulation layers. Refractory materials used in this zone must ensure tightness as well as chemical resistance to molten aluminium and sodium- and fluorine-based compounds. Resistance to bath and molten metal penetration is particularly critical, as infiltration into deeper layers may lead to erosion, loss of insulating properties and, consequently, a reduction in the operational lifetime of the electrolytic cell.

The main function of the insulation layer is to reduce heat losses from the electrolytic cell and to maintain stable thermal conditions of the process.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryPenetration of the cryolite bath and liquid aluminium through the barrier layer — reaching the insulation layers can shorten the pot's service life by several years.

Continuous exposure to sodium and fluorine compounds under electric current flow, accelerating chemical degradation of the refractory ceramics in the cathode zone.

Maintaining optimal thermal balance of the pot — excessive heat loss through insulation increases electricity consumption, while insufficient insulation jeopardises the stability of the electrolysis process.

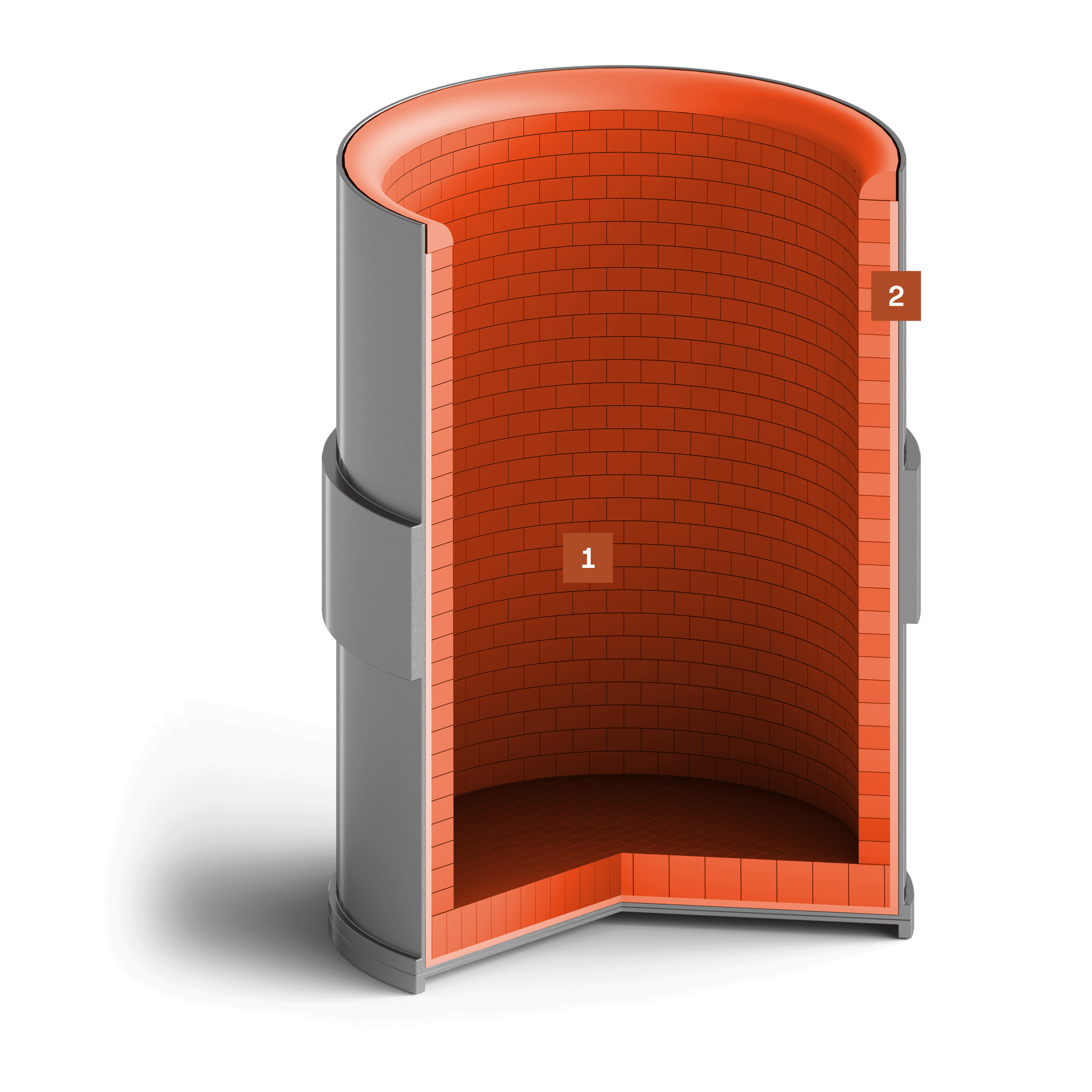

Transport Ladle – overview of solutions

The transport ladle is used for transferring molten aluminium from the electrolytic cell to the casthouse. Due to the high metal temperature—exceeding 700 °C—and significant temperature differences between the molten aluminium and the surrounding environment, this equipment requires effective thermal insulation and a properly designed refractory lining. Transport ladles may be manufactured as open or closed units and are often equipped with tilting mechanisms and tapping valves. Their design must ensure safe transport without excessive heat losses or the risk of metal solidification. Frequent heating and cooling cycles, thermal shocks and the potential spillage of molten aluminium pose serious challenges to the durability of refractory materials. Maintaining the integrity of the refractory lining is critical, as it must provide resistance to aggressive molten aluminium as well as dimensional and thermal stability throughout the entire operating cycle.

Scope of offer: Lining design Refractory products supply Lining installation services

The working lining is in direct contact with molten aluminium and represents the most heavily loaded part of the ladle lining. It is exposed to intense metal attack, possible contact with oxides and local overheating, particularly near the ladle walls and tapping area. A common risk is the penetration of molten aluminium into the refractory structure, leading to weakening, delamination or cracking. Materials used in this layer must exhibit high resistance to metallic corrosion, low wettability by molten aluminium and high resistance to thermal shock. Low porosity and high chemical purity are strongly recommended.

This layer separates the working lining from the external steel shell of the ladle. Its primary function is to minimise heat losses during the transport of molten metal. At the same time, it acts as a compensating layer during thermal cycling, reducing stresses within the lining structure. Lightweight refractory materials or insulating boards are typically applied in this zone. They must provide low thermal conductivity, resistance to heating cycles and sufficient mechanical strength at low bulk density.

What can we help with?

If you would like to receive free advice or inquire about the selection of refractory linings, leave us your contact details, and we will call you!

Send an inquiryFrequent heating and cooling cycles cause intense thermal shock — the primary cause of cracking and delamination of the ladle's working lining.

Penetration of liquid aluminium into the ceramic structure in the metal contact zone, weakening the lining and creating a risk of leakage during transport.

The need to minimise heat loss while keeping ladle weight low — requires precise selection of insulation materials capable of withstanding repeated thermal cycles.

Why choose PCO?

We are able to manufacture complex shapes and prefabricated components with high dimensional accuracy

All refractory bricks, mortars and castables available from a single manufacturer

Product portfolio developed to the specifications of leading aluminum manufacturers

Selected Products and Services for the Coke Industry

Top Blocks – prefabricated closure shapes for flow channel walls

NORMATON AX28

Refractory mortars for brickwork in anode furnace linings

Contact us

Please select the option that best describes the subject you want to discuss with us. This will help us direct your inquiry to the right person at PCO.